Overview

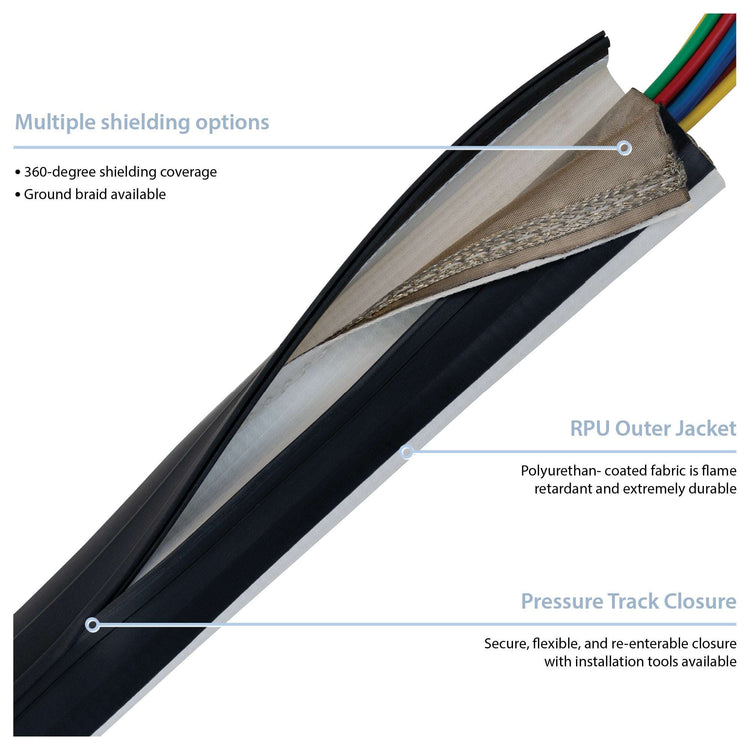

- RPU jacket is tear resistant and flame retardant

- Pressure track closure system for a secure seal

- Z-3250 EMI-shielding cloth is lightweight and corrosion resistant

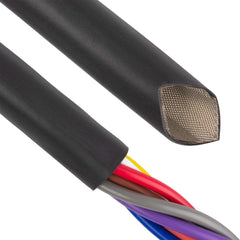

Zip-Shield® (RPU) combines a tear-resistant, flame-retardant, polyurethane-coated polyester fabric jacket with EMI shielding designed to protect cables and wires in demanding environments. The integrated EMI shielding layer can be a metalized fabric, wire mesh, or high performance foil, offering protection from electromagnetic interference (EMI), radio frequency interference (RFI), and electromagnetic fields (EMF).

The RPU-17 jacket is coated with polyurethane for added durability and environmental protection. The RF-sealed Z-Track pressure track closure ensures a secure and reliable seal while providing easy re-entry for maintenance, making it ideal for applications where safety, EMI shielding, and rugged performance are critical.

Zip-Shield® (RPU) is an excellent choice for medical and clean room environments where the use of PVC is restricted. The polyurethane and polyester fabric is non-PVC, flame retardant, and tear-resistant, meeting the high safety and contamination standards these environments demand. Additionally, its internal EMI shielding layer ensures critical medical devices and equipment remain protected from harmful electromagnetic interference. The re-enterable Z-Track closure allows for easy maintenance without compromising the sealed environment, making it ideal for clean room applications requiring precision and low particulate generation.

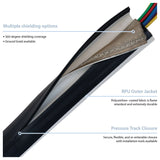

- EMI Shielding: Internal 360 degree shielding to block EMI, RFI, and EMF.

- Flame Retardant Jacket: Polyurethane-coated polyester fabric for high durability and safety.

- Z-Track Closure: RF-sealed interlocking track system for secure and re-enterable access.

- Reliable Protection: Prevents EMI from interfering with sensitive electronics.

- Durable Performance: Tear-resistant and flame-retardant for long-lasting use.

- Easy Maintenance: Re-enterable design allows for convenient adjustments or repairs.

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

RPU-17

- Solvent Resistance:

- REACH:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Z-Track (PFR)

Z-3250

SHX-4 (SnCuFe)

SH1 (Foil Shielding)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | SHRINK-N-SHIELD® (3:1) EMI SHIELDED HEAT SHRINK TUBING |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | A heat-shrink tubing that provides exceptional shielding from EMI, RFI and EMF. |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | |

| Installation Type | Pull-Through | Pull-Through | Pull-Through |

| Purpose | EMI Shielding | Sleeve | Small Diameters |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -67°F | -40°F | -67°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 275°F | 302°F | 275°F |

| Flexibility | |||

| View | View | View |

Guides

Zip-Shield® (RPU) Cable Bundling with EMI Shielding

A protective, tear-resistant and flame-retardant polyurethane-coated polyester fabric jacket with a sewn-in EMI-shielding cloth, mesh, or foil featuring a Z-Track pressure track closure

Drawing Number(s): ZT15-17-003

Selected Part Number: ZT15-17-003-0.375-W-B

Features

Benefits

Zip-Shield® (RPU) Cable Bundling with EMI Shielding

SHIELDING EFFECTIVENESS - Z-3250, SHX-4 (SnCuFe), SH1 (Foil Shielding)

Zip-Shield® (RPU) Cable Bundling with EMI Shielding

MATERIAL SPECIFICATIONS