Overview

- Excellent EMI-shielding performance

- Adhesive closure provides secure seal

- Wrap-around design for easy installation

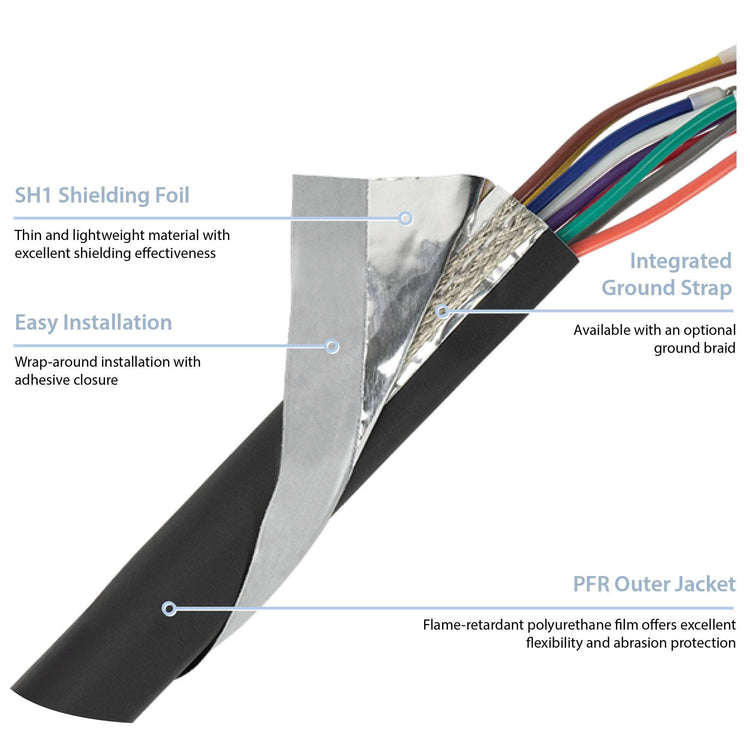

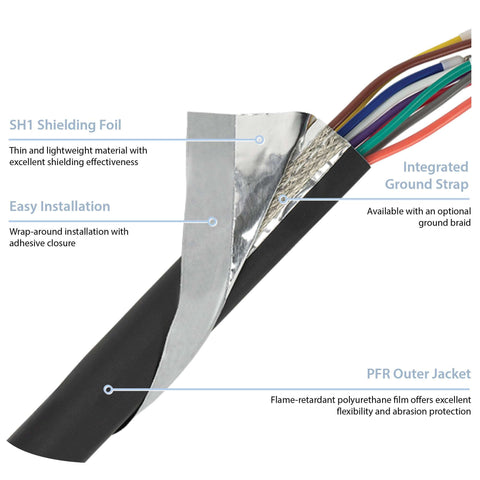

Z-Shield® (Al) is a wrap-around, EMI-shielding solution providing exceptional protection from damaging electromagnetic interference. The jacket utilizes PFR-8235-a lightweight, thin and flame-retardant polyurethane film. The material resists abrasion, chemicals and UV, and is RoHS compliant and PVC-free.

The SH1 shielding foil, made of a bright-finished aluminum foil equipped with a polyester film backing, offers the best of EMI shielding. The adhesive closure provides a secure, permanent seal around components for complete, 360-degree protection. Z-Shield® (Al) has an optional 15 AWG or 27 AWG tin/copper drain wire for applications requiring grounding.

Z-Shield® (Al) is an ideal choice for applications that will not experience any flexing or movement. If the application needs more flexibility, the Z-Shield® product line offers products with EMI shielding cloths that can move without compromising the shielding performance, such as Z-Shield® (3250), Z-Shield® (5080) and Z-Shield® (7200).

Z-Shield® (Al) accommodates round, flat or rectangular components with diameters ranging from 0.25" to 4". Custom sizes and shapes are available upon request. Z-Shield® (Al) has an operational temperature range of -65°F to 250°F (-54°C to 121°C).

- Engineered for round, flat or rectangular components

- Adhesive closure provides secure seal

- Optional 15 AWG or 27 AWG tin/copper drain wire

- Wrap-around solution makes for quick and easy installation

- SH1 shielding foil protects against damaging EMI

- Flame-retardant, abrasion-resistant and chemical-resistant jacket

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Closure:

- Material:

- Flammability:

- Diameter:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

PFR-8235

- Chemical Resistance:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

SH1 (Foil Shielding)

Nylon Thread

None

15 AWG Braided Ground Straps

27 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | ZIP-MESH® (AL) EMI SHIELDING MESH TAPE |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | An EMI shielding tape that has a tinned copper mesh with an aluminum polyester tape and a self-adhesive closure. |

| Closure | Tape (Electrically Conductive) | Adhesive | Tape (High Temperature) |

| RoHS | RoHS-10 | RoHS-10 | RoHS-6 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Tape |

| Min Temperature | Moderate | Moderate | Moderate |

| Minimum Operating Temperature | °F | -49°F | -40°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 158°F | 250°F | 300°F |

| Flexibility | |||

| View | View | View |

Guides

Z-Shield® (Al) EMI Shielding Wrap

A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil.

Drawing Number(s): ZT94-04-003, ZT96-04-029, ZT97-04-023, ZT20-04-006, ZT94-04-004

Selected Part Number: ZT94-04-003-0.25-B

Features

Benefits

Z-Shield® (Al) EMI Shielding Wrap

SHIELDING EFFECTIVENESS - SH1 (Foil Shielding)

Z-Shield® (Al) EMI Shielding Wrap

MATERIAL SPECIFICATIONS