Overview

- Jacketing options for a wide range of application requirements

- Pressure track closure system for a secure seal

- EMI-shielding cloth is lightweight and corrosion resistant

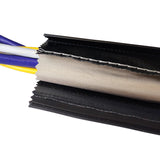

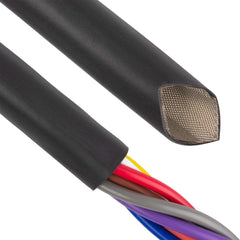

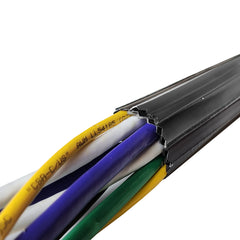

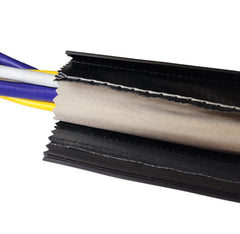

Zip-Shield® (PVL) is an EMI-shielding solution consisting of a jacket with a sewn-in shielding cloth, mesh or foil and a pressure track. A wide range of jacketing options are offered based on application requirements, whether you need a jacket that is military grade and flame retardant or one that is PVC free and provides exceptional abrasion resistance. The 3250 EMI shielding cloth offers protection from EMI, RFI, and EMF, so you can be confident that your components will not be compromised by these damaging interferences.

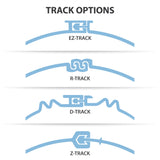

Zip-Shield® (PVL) is typically paired with the R-Track or the Z-Track. Either pressure track system will be easy to seal and offer a long-lasting closure, and if re-entry is required, you can easily break out components. The Z-Track is a medium duty pressure track closure with an arrowhead and channel interlock system, and it is the most versatile pressure track option. The Z-Track can be sealed with our ZTZ-SP plier tool. The R-Track is a light duty pressure track closure and is similar to a zip-lock closure. The R-Track can be sealed manually with a thumb or with an SLR slider tool.

Zippertubing® can also manufacture Zip-Shield® (PVL) with our other pressure track closures upon request.

Jacketing options for Zip-Shield® (PVL) include:

PVL-10: Extremely flexible and lightweight woven polyester fabric that has a PVC coating in addition to high tear strength and abrasion protection.

- Engineered for diameters ranging from 0.375" to 4", with custom sizes available upon request

- Provides 360-degree protection of components with inner overlap of EMI-shielding cloth

- Pressure track is heat sealed to jacketing for a strong bond

- Secure pressure track seal with ability to re-enter as needed

- EMI shielding for protection against EMI, RFI, and EMF

- Wide range of jacketing options to fit any application or condition

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

PVL-10

- Mil-Spec:

- REACH:

- Chemical Resistance:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

R-Track (PVC)

Z-Track (PVC)

Z-3250

SHX-4 (SnCuFe)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | SHRINK-N-SHIELD® (3:1) EMI SHIELDED HEAT SHRINK TUBING |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | A heat-shrink tubing that provides exceptional shielding from EMI, RFI and EMF. |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | |

| Installation Type | Pull-Through | Pull-Through | Pull-Through |

| Purpose | EMI Shielding | Sleeve | Small Diameters |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -67°F | -40°F | -67°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 275°F | 302°F | 275°F |

| Flexibility | |||

| View | View | View |

Guides

Zip-Shield® (PVL) Cable Bundling with EMI Shielding

A protective jacket with a sewn-in EMI-shielding cloth, mesh or foil that features a pressure track closure.

Drawing Number(s): ZT97-17-145, ZT97-17-148

Selected Part Number: ZT97-17-145-0.375-B-B

Features

Benefits

Zip-Shield® (PVL) Cable Bundling with EMI Shielding

SHIELDING EFFECTIVENESS - Z-3250, SHX-4 (SnCuFe)

Zip-Shield® (PVL) Cable Bundling with EMI Shielding

MATERIAL SPECIFICATIONS