Overview

- PVL-10 jacketing meets MIL-C-43006G, Type II, Class 1 requirements

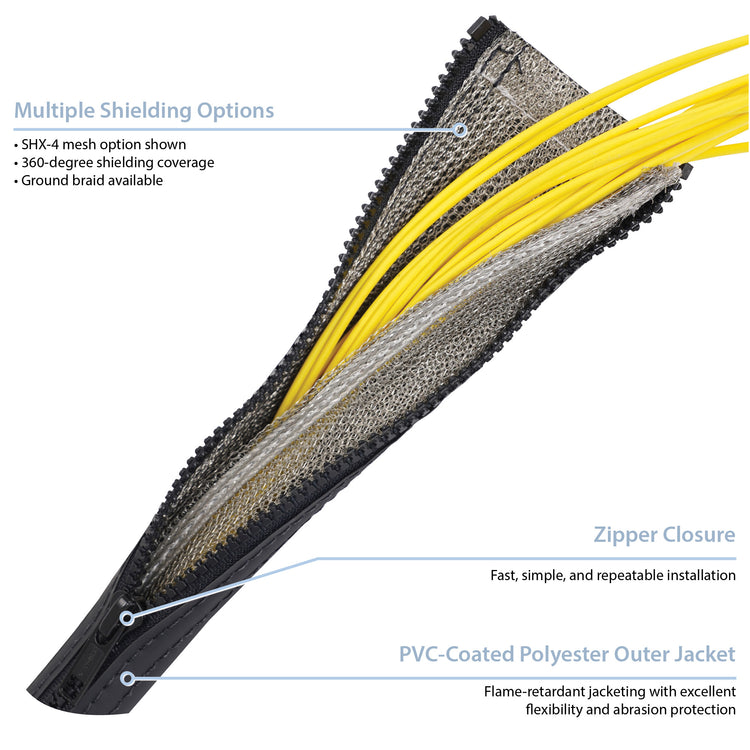

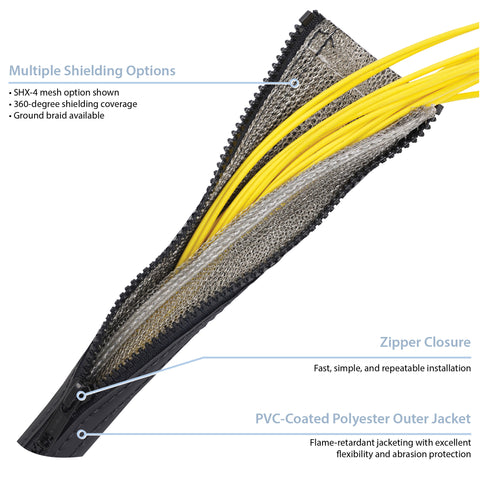

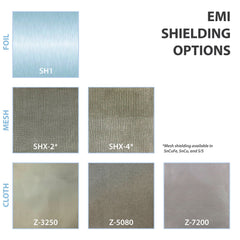

- SHX-4 (SnCuFe) shielding mesh provides good EMI shielding

- Zipper closure system requires no additional tools for installation

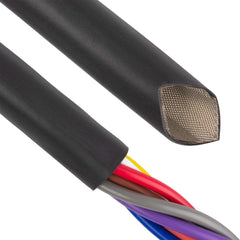

Zipper-Mesh™ (PVL) cable shielding is a convenient and efficient method of providing EMI/EMP protection to harnesses and wire bundles. It is a highly-flexible shield constructed of 4-ply knitted wire mesh utilizing an internal shield overlap, an integral grounding strap, and a heavy duty zipper closure. The zipper closure mechanism allows installation to be "tool-free", and re-entry to be very simple for cable repair or modification. The Mesh jacket is protected with an outer jacket of flame retardant PVL-10, providing a lightweight, abrasion resistant surface with six color options.

- Zipper closure allows for quick and easy access to components as needed

- Optional braided copper wire for grounding capabilities

- Operational temperature range of -40°F to 180°F (-40°C to 82°C)

- Jacketing is abrasion resistant and flame retardant

- Shielding mesh is durable for rugged conditions

- PVL-10 is available in six different colors for color-coding

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

PVL-10

- Mil-Spec:

- REACH:

- Chemical Resistance:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Zipper (Nylon)

SHX-4 (SnCuFe)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | ZIP-SHIELD® (63) CABLE BUNDLING WITH EMI SHIELDING |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | A protective jacket made from a flexible, wrap-around PVC film with a sewn-in EMI-shielding cloth, mesh or foil—featuring a pressure track closure. |

| Closure | R-Track (PVC), Z-Track (PVC), D-Track (PVC), EZ-Track (PVC) | ||

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | Wrap-Around |

| Purpose | EMI Shielding | Sleeve | Sleeve |

| Min Temperature | Extreme | Moderate | Low |

| Minimum Operating Temperature | -67°F | -40°F | -4°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 275°F | 302°F | 221°F |

| Flexibility | |||

| View | View | View |

Zipper-Mesh (PVL) Cable Bundling with EMI Shielding

A wrap-around EMI shielding solution that combines the lightweight PVL-10 jacketing with the durable SHX-4 shielding mesh and zipper closure.

Drawing Number(s): ZT02-07-001

Selected Part Number: ZT02-07-001-0.5-B

Features

Benefits

Zipper-Mesh (PVL) Cable Bundling with EMI Shielding

SHIELDING EFFECTIVENESS - SHX-4 (SnCuFe)

Zipper-Mesh (PVL) Cable Bundling with EMI Shielding

MATERIAL SPECIFICATIONS