Overview

- High-performance, PTFE-coated fiberglass jacket

- Chemical resistant and offers military-grade protection

- Handles high and low temperatures

- Equipped with EMI shielding foil and pressure track closure

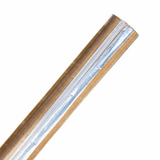

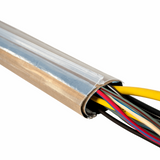

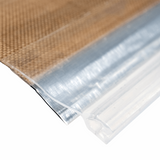

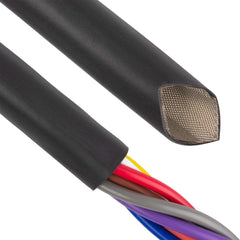

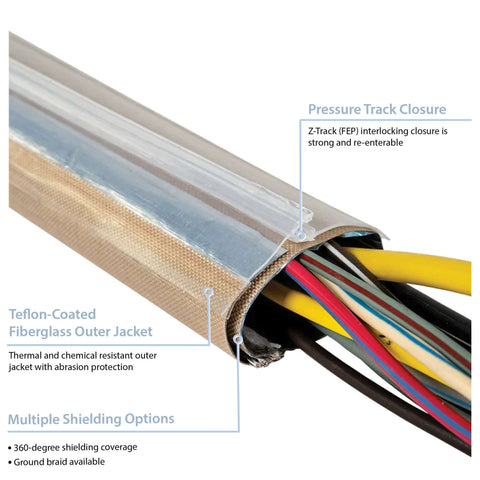

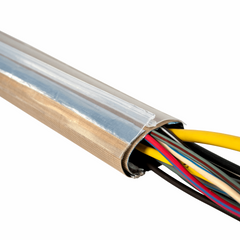

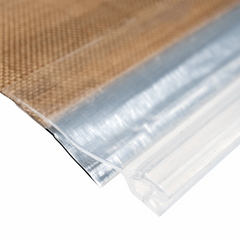

Zip-Shield® (PTG) pairs a sewn-in EMI-shielded cloth, mesh or SH1 foil shielding, for EMI protection, with a lightweight, PTG-5 jacket made from PTFE-coated fiberglass fabric that is both military grade and highly chemical resistant. Zip-Shield® (PTG) provides durable protection in low – to high-temperature environments and has a pressure track closure. Optional sewn-in 15 AWG drain strap can be used for grounded applications.

Zip-Shield® (PTG) is equipped with Zippertubing’s FEP Z-Track closure. This medium-duty pressure track closure is highly versatile and has an arrowhead-and-channel interlock system. Z-Track can be sealed with our ZTZ-SP plier tool.

- Engineered for diameters ranging from 0.375” to 4”, with custom sizes available upon request

- Z-Track closure is heat sealed to jacketing for strong bond

- Optional 15 AWG braided ground strap

- Superior EMI shielding with SH1 foil

- Can be used in high-temperature and chemically-abrasive environments

- Can be engineered for round, flat, or custom cables

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shielding:

- Shielding Material:

PTG-5

- Mil-Spec:

- Durability:

- Break Strength:

- REACH:

- Dielectric Strength:

- Flammability:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

Z-Track (FEP)

SH1 (Foil Shielding)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Guides

Zip-Shield® (PTG) Cable Bundling with EMI Shielding

A lightweight, PTFE-coated fiberglass protective jacket paired with a sewn-in EMI- shielding cloth, mesh or foil featuring a pressure track closure.

Drawing Number(s): ZT10-17-002

Selected Part Number: ZT10-17-002-0.375-T-C

Features

Benefits

Zip-Shield® (PTG) Cable Bundling with EMI Shielding

SHIELDING EFFECTIVENESS - SH1 (Foil Shielding)

Zip-Shield® (PTG) Cable Bundling with EMI Shielding

MATERIAL SPECIFICATIONS