Overview

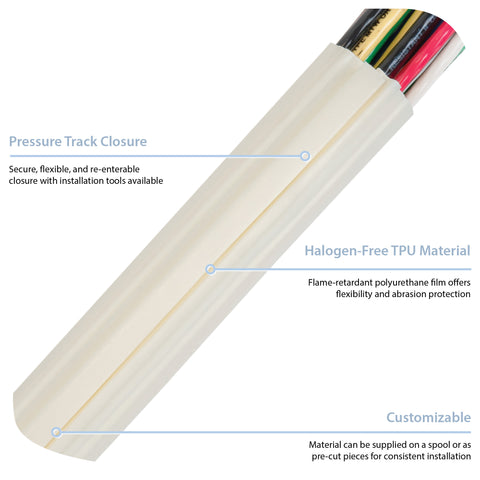

- All-white cable bundling solution ideal for medical or clean room applications

- Best in abrasion resistance, and is also resistant to microorganisms and ozone damage

- Pressure track is RF welded to jacketing for a clean, strong bonding

Zip-On® (TPU) pairs the durable TPU jacketing with the secure, easy to close EZ-Track® (TPU) pressure track. The TPU jacketing is an extruded thermoplastic polyurethane material. This jacketing offers the best protection from abrasion, is highly resistant to microorganisms, as well as being ozone resistant (Stage 0, “Crack Free”). The TPU is also UL-rated for flammability with meeting UL 94 V-0.

The TPU jacketing is RF welded to the pressure track EZ-Track® (TPU). This closure system is also made of a thermoplastic polyurethane material, which makes a completely halogen-free and flame-retardant solution. The EZ-Track® (TPU) can be closed using either the EZ-Slider for shorter runs or the ZTEZ-SP Plier for longer runs, making installation quick and easy.

Zip-On® (TPU) can be cut to any desired length, and is offered for diameters ranging from 0.4375” to 6”, with custom sizes available upon request. The operational temperature range is -40°F to 257°F (-40°C to 125°C).

*Zip-On® (TPU) is not specifically manufactured using a clean room in sterile conditions, but with the right procedures, it could be used in the medical field, including in hospitals, operating rooms, trauma centers, and emergency rooms.

- The pressure track makes this solution fit for clean rooms, hospitals, trauma centers, and emergency rooms

- Can be cut to any desired length

- Operational temperature range of -40°F to 257°F (-40°C to 125°C)

- Wrap-around capability allows for no disconnection of wires required

- UL-rated for flammability; UL 94 V-0

- Ozone resistant; Stage 0, “Crack Free”

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

TPU-20

- Durability:

- REACH:

- Elongation:

- Flammability:

- Color:

- Thickness:

- Thickness Variance:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

- Ozone Resistance:

EZ-Track (TPU)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Guides

Zip-On® (TPU) Polyurethane Cable Bundling

A wrap-around, fire-retardant, thermoplastic polyurethane cable management solution, utilizing a pressure track closure.

Drawing Number(s): ZT16-11-002, ZT17-16-002

Selected Part Number: ZT16-11-002-0.4375-W-X600.0

Features

Benefits

Zip-On® (TPU) Polyurethane Cable Bundling

Zip-On® (TPU) Polyurethane Cable Bundling

MATERIAL SPECIFICATIONS