Overview

- Fluorinated ethylene propylene (FEP) is self-extinguishing, as well as abrasion, fluid, and chemical resistant

- Z-Track provides a secure closure around wires or cables

- Can withstand extreme temperatures of -238°F to 400°F (-150°C to 204°C)

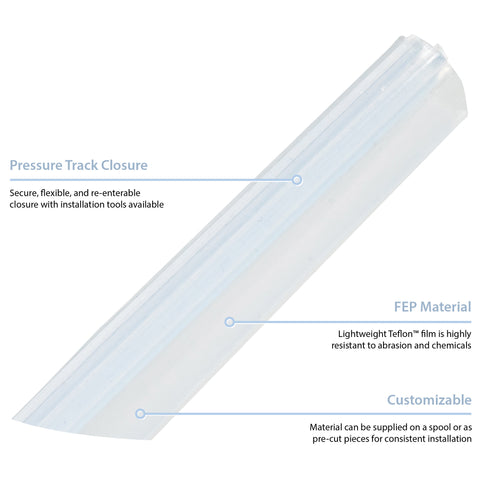

Zip-On® (FEP) combines a Teflon® jacketing and pressure track to create a lightweight, durable cable management solution. The FEP jacketing is a clear Teflon® film that is abrasion, fluid, and chemical resistant. The material is also self-extinguishing and can handle extremely low and moderately high temperatures. The film is lightweight at only 0.005” thick, making this ideal for applications with limited weight and space availability.

The Z-Track (FEP) is also made from a Teflon® material with similar characteristics to the FEP jacketing. The pressure track can handle low and high temperatures, and offers a secure seal around components. The Z-Track utilizes an arrowhead and channel interlocking system that provides a strong barrier from debris penetrating inside to the wires or cables.

Zip-On® (FEP) is offered for diameters ranging from 0.375” to 4”, with custom shapes and sizes available upon request. The operational temperature is -238°F to 400°F (-150°C to 204°C).

- Ideal cable management solution for aerospace applications

- Clear jacketing and pressure track allows for easy visibility to components inside

- Operational temperature is -238°F to 400°F (-150°C to 204°C)

- Low-outgassing, self-extinguishing Teflon® material

- Z-Track is the strongest pressure track offered by Zippertubing®

- Resistant to abrasion, fluids, and chemicals

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Flammability:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

FEP-5

- Ratings:

- Surface Resistivity:

- Dielectric Volts/Mil:

- Dielectric Constant:

- Dielectric Strength:

- Volume Resistivity:

- Flammability:

- Color:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Melt Temperature:

- RoHS:

- Tear Strength:

- Dissipation Factor:

- Tensile Strength:

Z-Track (FEP)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Guides

Zip-On® (FEP) Clear Teflon Cable Bundling

A wrap-around Teflon® solution pairing a clear, non-flammable, low-outgassing jacketing and pressure track for exceptional cable bundling and protection.

Drawing Number(s): ZT19-16-004

Selected Part Number: ZT19-16-004-0.5-C-C

Features

Benefits

Zip-On® (FEP) Clear Teflon Cable Bundling

Zip-On® (FEP) Clear Teflon Cable Bundling

MATERIAL SPECIFICATIONS