Overview

- Military-grade jacket is abrasion- and tear resistant

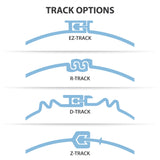

- Choose from four different pressure track closures

- Offered in a variety of colors

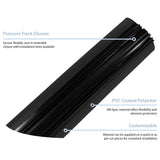

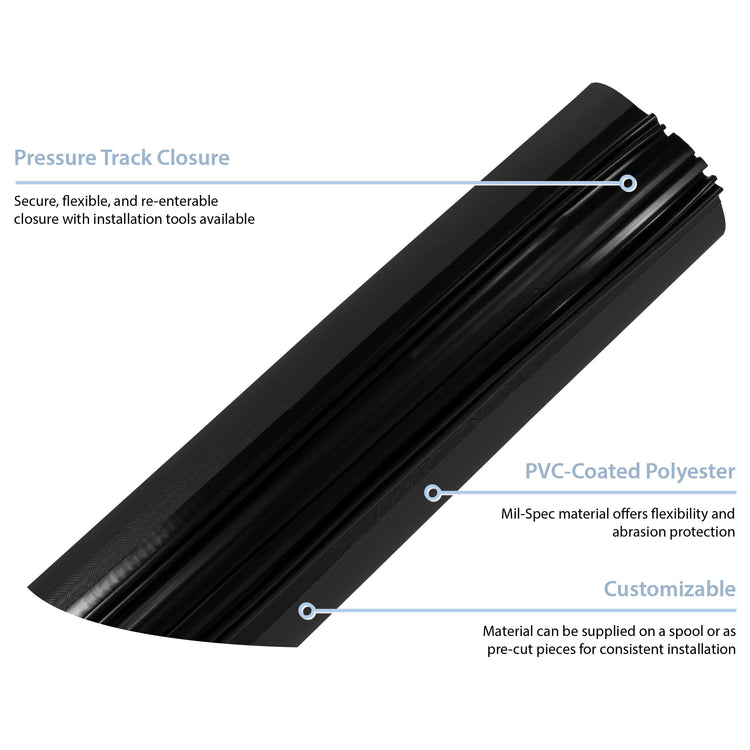

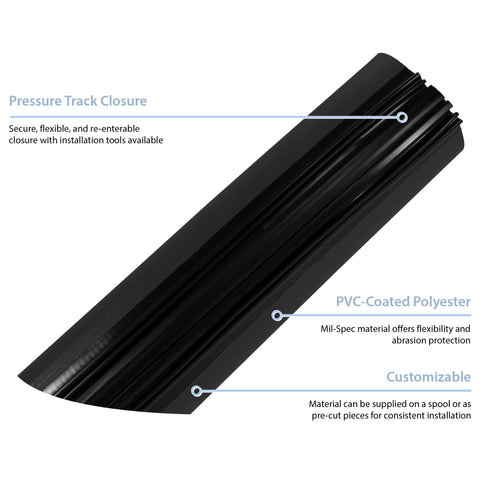

Zip-On® (DVH) is a wrap-around cable management and protection solution featuring a heat-sealed, durable jacket and pressure track closure. The DVH jacketing utilizes woven polyester fabric coated with PVC on both sides; and offers better abrasion-, tear- and fluid resistance. Zip-On® (DVH) is military grade, making it an ideal choice for applications exposed to rugged environments or conditions.

The DVH jacketing is offered in two thicknesses: 20 mil (DVH-20) and 40 mil (DVH-40). DVH-20 is for general purpose jacketing, while DVH-40 is for heavier-duty protection.

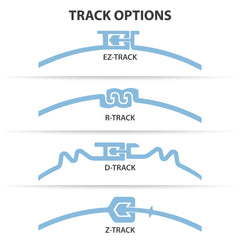

Zip-On® (DVH) is typically equipped with our Z-Track or D-Track-LT PVC pressure tracks.

The Z-Track is an arrowhead-and-channel closure that provides a secure seal and is the strongest pressure track closure Zippertubing® offers. The Z-Track pressure track can be installed with one of our plier or slider tools. The plier tool is great for long cable runs, while the slider tool is better for shorter cable runs.

The D-Track-LT is a heavy-duty track that is ideal for more rugged environments. The seal provides a strong closure and withstands fluids and abrasion. The D-Track-LT pressure track can be closed with the SLD slider or ZTD-SP plier tool.

Zip-On® (DVH) is also customizable. Zippertubing® can manufacture Zip-On® (DVH) with any of our other PVC pressure tracks, such as EZ-Track™ and R-Track.

Zip-On® (DVH) product diameters range from 0.375” to 6.25” with custom sizes and colors available. The operational temperature range is -34°F to 185°F (-37°C to 85°C).

- Range of pressure track options allows you to pick the perfect type of closure system, depending on application needs

- Offered in diameters from 0.375” to 6.25” with custom sizes and colors available

- Operational temperature range of -34°F to 185°F (-37°C to 85°C)

- DVH jacketing offers good durability for harsh environments and conditions

- Can be cut to any length required

- Ideal for color coding of components, with an array of color options available

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

DVH-20

- Mil-Spec:

- Durability:

- Coating:

- REACH:

- Flame Retardant:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

DVH-40

- Mil-Spec:

- REACH:

- Fungicide:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tear Strength:

- Tensile Strength:

D-Track (PVC)

Z-Track (PVC)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Guides

Zip-On® (DVH) Cable Bundling

Zip-On® (DVH) is a wrap-around cable management and protection solution featuring a heat-sealed, durable jacket and pressure track closure—available in a variety of colors.

Drawing Number(s): ZT05-16-005, ZT11-16-002

Selected Part Number: ZT05-16-005-0.75-B-B

Features

Benefits

Zip-On® (DVH) Cable Bundling

Zip-On® (DVH) Cable Bundling

MATERIAL SPECIFICATIONS