Overview

- Easy-to-install snap closure

- Flexible, abrasion-resistant and flame-retardant jacket

- Ideal for automotive, truck and bus applications

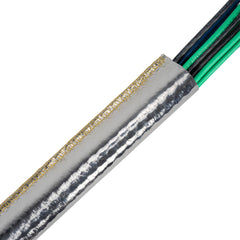

Snap-Grip® (SAM-1000) is a heat shielding solution made from a silicone, polymer-coated fiberglass with an aluminum foil outer layer, paired with stainless-steel snap buttons. This heat-shielding solution can handle up to 464°F, making it the ideal solution for wires or cables exposed to continuously high temperatures. The SAM-1000 jacketing is durable and has good abrasion resistance—great for automotive, truck and bus applications. This material is also self-extinguishing and has tested per SAE J2302 for Thermal Effectiveness.

The stainless-steel snap buttons offer quick installation and easy accessibility to the components inside. The space in between snaps allows wires and cables to break out without cutting any of the protective jacketing. The material can be cut to any desired length if needed. For applications requiring a quick, toolless installation right on the job without disassembly of components, Snap-Grip® (SAM-1000) is the perfect solution.

We offer Snap-Grip® (SAM-1000) in diameters ranging from 0.75” to 2.75”, with custom sizes available upon request. The operational temperature range of Snap-Grip® (SAM-1000) is -58°F to 464°F (-50°C to 240°C); and up to 518°F (270°C) for short bursts.

- Jacket is self-extinguishing and tested per SAE J2302

- Space between snaps allows for wire or cable break outs

- Aluminumized silicone-coated fiberglass material for heat protection

- Can be cut to any desired length

- Protects components from continuous exposure up to 464°F

- Snap-button closure system allows a toolless installation

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

SAM-1000

- REACH:

- Chemical Resistance:

- Flammability:

- Thickness:

- Thickness Variance:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tear Strength:

Stainless Steel Snaps

Similar products

|

|

|

|

| NAME | ZTT® (ALR-550) HIGH TEMP PULL-THROUGH CABLE SLEEVE | ZIPPER-MESH (ALHTG-65) EMI & HEAT SHIELDED JACKETING | ZTT® (ALHTG) HEAT SHIELDED PULL-THROUGH CABLE SLEEVE |

| DESCRIPTION | A pull-through, flexible heat shielding sleeve that protects components from continuous temperatures as high as 1,022°F. | An all-in-one, wrap-around solution combining the heat shielding of the ALHTG-65 with the EMI shielding of the knitted SHX-4 mesh and a brass zipper. | A heat shielding sleeve that offers complete protection from temperatures up to 1,202°F and is equipped with a cloth leader for easy pull-through installation. |

| Closure | Stainless Steel Reinforced Kevlar Thread | Toothed Zipper (High-Temp Brass) | Stainless Steel Reinforced Kevlar Thread |

| RoHS | |||

| Abrasion Resistance | Good | Good | Good |

| Installation Type | Pull-Through | Wrap-Around | Pull-Through |

| Purpose | Sleeve | EMI Shielding | Sleeve |

| Min Temperature | Extreme | Moderate | Moderate |

| Minimum Operating Temperature | -58°F | -32°F | -32°F |

| Max Temperature | Extreme | Extreme | |

| Maximum Operating Temperature | 1022°F | 399°F | 1202°F |

| Flexibility | Better | ||

| View | View | View |

Snap-Grip® (SAM-1000) Heat Shielded Cable Bundling

A heat shielding solution featuring a silicone, polymer-coated fiberglass jacket with stainless-steel snaps that protects components from temperatures up to 464°F.

Drawing Number(s): ZT07-08-008

Selected Part Number: ZT07-08-008-0.375

Features

Benefits

Snap-Grip® (SAM-1000) Heat Shielded Cable Bundling

Snap-Grip® (SAM-1000) Heat Shielded Cable Bundling

MATERIAL SPECIFICATIONS