Overview

- Jacketing that protects from moderately high temperatures up to 400°F

- EMI shielding mesh is durable and will last through rugged conditions

- Brass zipper closure allows for quick and easy installation without additional tools

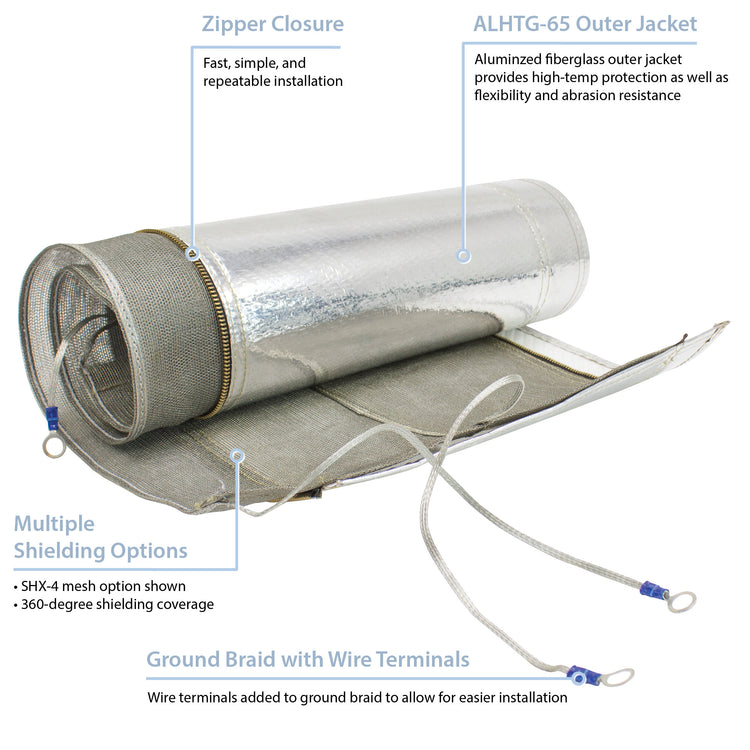

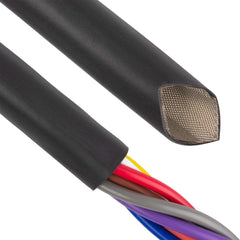

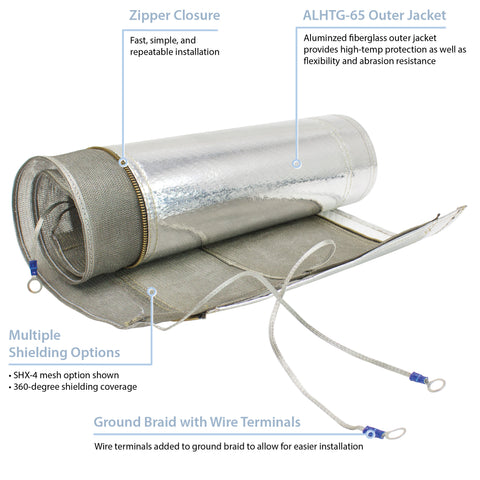

Zipper-Mesh™ (ALHTG-65) is the all-inclusive solution for applications exposed to heat and EMI. Pairing the ALHTG-65 jacketing that protects from moderately high temperatures with the shielding effectiveness of the SHX-4 SnCuFe mesh creates a product that solves two component challenges in one.

The ALHTG-65 thermal jacketing is a woven fiberglass coated with an aluminum/PET film on one side and bonded using a silicone adhesive. The fiberglass is also treated with SiO2 for superior heat reflection. The jacketing perimeter is sealed utilizing the ALS-5 thermal material to finish off the edges with a clean appearance, as well as to protect the installer from excessive fibers becoming loose from the ALHTG material.

The SHX-4 SnCuFe shielding mesh provides good shielding from EMI, RFI, and EMF. The mesh is a 4-ply knitted tin-plated, copper clad, steel wire. The SHX-4 is sewn to the ALHTG jacketing using a strong, durable stainless-steel Kevlar thread, which ensures a lasting connection between materials. The shielding mesh also has a 15 AWG ground braid sewn in using a white Nylon thread and is equipped with a vinyl-insulated wire terminal.

The brass zipper allows for quick, on-the-job installation with no disconnection required. Simply wrap Zipper-Mesh™ (ALHTG-65) around the components, and zip closed; re-entering to wires or cables is just as easy.

Zipper-Mesh™ (ALHTG-65) is offered for 2.5” and 3.5” diameters, with custom shapes and sizes available upon request. The operational temperature range of -32°F to 400°F (-36°C to 204°C).

- Zipper closure system provides ability to access components even after installation

- Braided strap with wire terminal for grounding capabilities

- Operational temperature range of -32°F to 400°F (-36°C to 204°C)

- Solves both heat shielding and EMI shielding component challenges

- Protect from temperatures up to 400°F

- Offers good EMI, RFI, and EMF shielding

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shielding:

- Shielding Material:

ALHTG-65

- REACH:

- Flame Retardant:

- Thickness:

- Thickness Variance:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tear Strength:

- Tensile Strength:

Toothed Zipper (High-Temp Brass)

SHX-4 (SnCuFe)

Stainless Steel Reinforced Kevlar Thread

15 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Zipper-Mesh (ALHTG-65) EMI & Heat Shielded Jacketing

An all-in-one, wrap-around solution combining the heat shielding of the ALHTG-65 with the EMI shielding of the knitted SHX-4 mesh and a brass zipper.

Drawing Number(s): ZT11-07-008

Selected Part Number: ZT11-07-008-05

Features

Benefits

Zipper-Mesh (ALHTG-65) EMI & Heat Shielded Jacketing

SHIELDING EFFECTIVENESS - SHX-4 (SnCuFe)

Zipper-Mesh (ALHTG-65) EMI & Heat Shielded Jacketing

MATERIAL SPECIFICATIONS