Overview

- Lightweight, high-temperature, fire-retardant material

- Best for heat barrier protection applications

- Operational temperature range of -58°F to 392°F

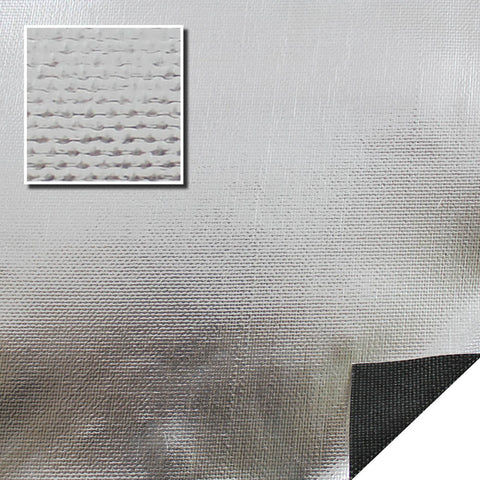

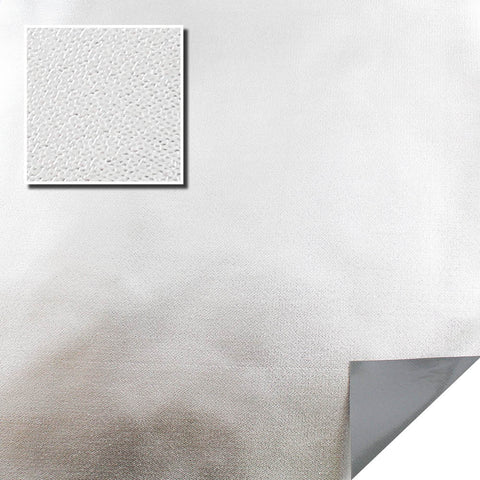

ZIPFLECT provides heat barrier protection by utilizing a high-temperature, polyester felt cloth material, which is laminated on one side to a reflective, Aluminum foil surface. Fire-retardant ZIPFLECT has an operational temperature range of -58°F to 392°F (-50°C to 200°C) with a maximum of 446°F (230°C) for short duration.

Specifications

Similar Materials

|

|

|

|

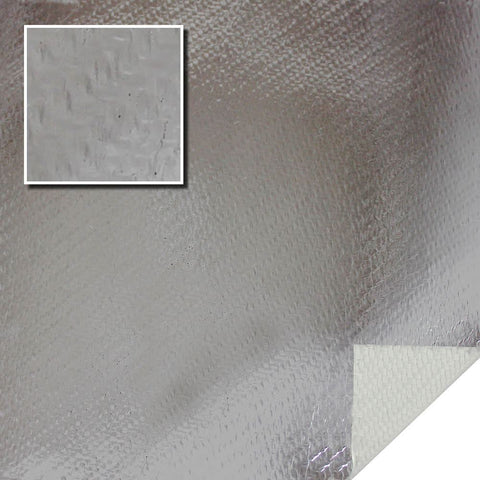

| NAME | SAM-1000 - ALUMINIZED SILICONE COATED FIBERGLASS FABRIC | ALSR-15 ALUMINIZED SILICONE COATED FIBERGLASS | ALHTG-65 HIGH TEMP ALUMINIZED FIBERGLASS FABRIC |

| DESCRIPTION | Rugged, Aluminized Silicone Coated Fiberglass, Up to 240 C | Mil-Spec Aluminized Silicone Coated Fiberglass, Up to 260°C | |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Better | Better | Good |

| Min Temperature | Extreme | Extreme | Moderate |

| Minimum Operating Temperature | -58°F | -67°F | -32°F |

| Max Temperature | Moderate | Extreme | Extreme |

| Maximum Operating Temperature | 464°F | 500°F | 1202°F |

| Flexibility | Better | Best | Better |

| View | View | View |

ZIPFLECT High-temp Polyester Felt Cloth

ZIPFLECT is a lightweight, fire-retardant material laminated to a reflective Aluminum surface for high temperature heat barrier protection.

Material Sprcification: 1229

- Lightweight, high-temperature, fire-retardant material

- Best for heat barrier protection applications

- Operational temperature range of -58°F to 392°F

SPECIFICATIONS

DESCRIPTION

ZIPFLECT provides heat barrier protection by utilizing a high-temperature, polyester felt cloth material, which is laminated on one side to a reflective, Aluminum foil surface. Fire-retardant ZIPFLECT has an operational temperature range of -58°F to 392°F (-50°C to 200°C) with a maximum of 446°F (230°C) for short duration.