Overview

- Ideal for Automotive, Truck & Bus Applications

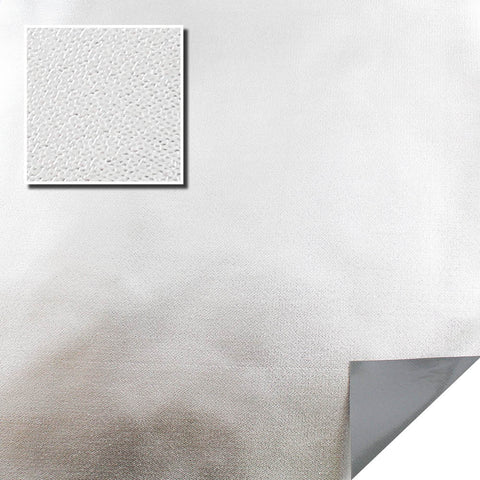

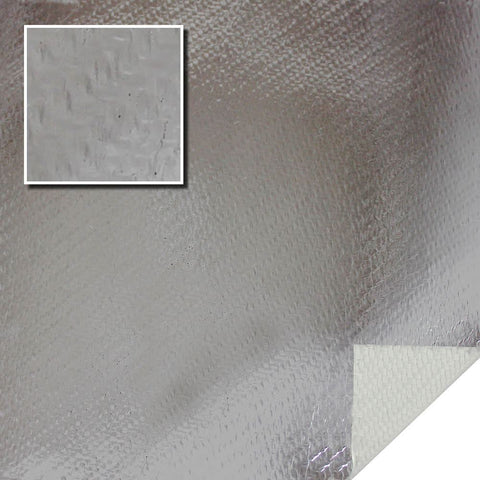

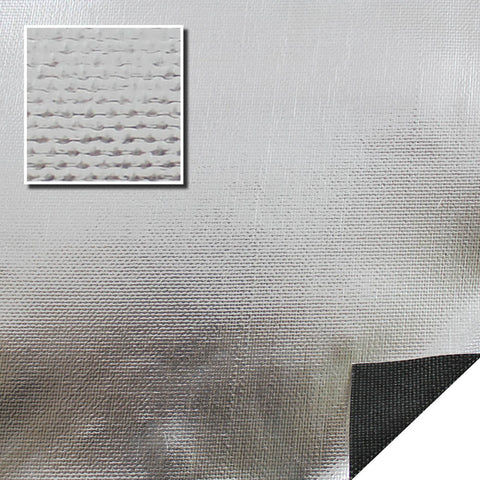

- Heat Reflective Silicone Coated Fiberglass

- Good Abraision Protection

- Custom Shapes Available

- Many Closures Available

- -50 to 240°C Operating Limit

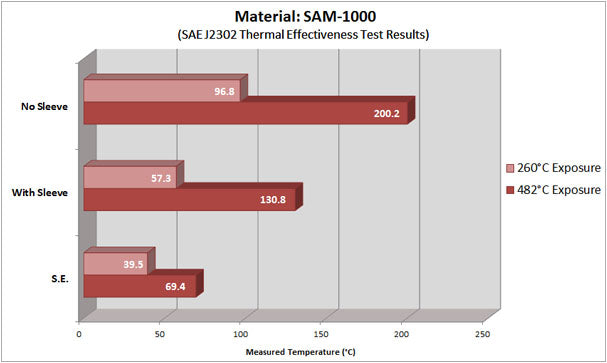

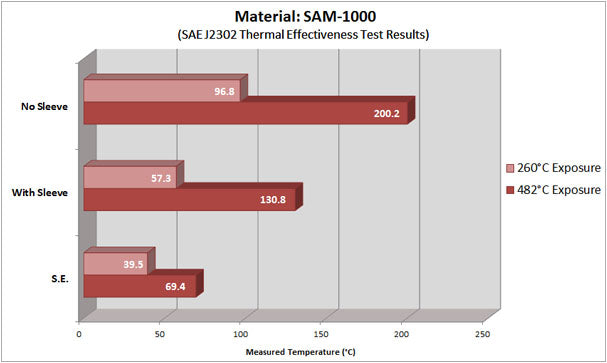

SAM-1000 is a heavy weight; Silicone impregnated fiberglass fabric with a heat reflective Aluminum Foil surface laminated on one side with a high temperature adhesive. The combination makes SAM-1000 a flexible and durable heat protection jacket material with outstanding abrasion characteristics. SAM-1000 is best in moderate temperature heat barrier applications where a mechanically tough jacket is required. The material has a thermal effectiveness value of 69+°C when tested to SAE J2302 requirements. These characteristics make SAM-1000 an ideal choice for under hood applications in the Automotive, Truck and Bus industry. The material has an operational temperature range of -50°C to 240°C.

Specifications

Thermal Effectiveness

Similar Materials

|

|

|

|

| NAME | ZIPFLECT HIGH-TEMP POLYESTER FELT CLOTH | ALSR-15 ALUMINIZED SILICONE COATED FIBERGLASS | ALHTG-65 HIGH TEMP ALUMINIZED FIBERGLASS FABRIC |

| DESCRIPTION | ZIPFLECT is a lightweight, fire-retardant material laminated to a reflective Aluminum surface for high temperature heat barrier protection. | Mil-Spec Aluminized Silicone Coated Fiberglass, Up to 260°C | |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Better | Good | |

| Min Temperature | Extreme | Extreme | Moderate |

| Minimum Operating Temperature | -58°F | -67°F | -32°F |

| Max Temperature | Moderate | Extreme | Extreme |

| Maximum Operating Temperature | 392°F | 500°F | 1202°F |

| Flexibility | Best | Better | |

| View | View | View |

SAM-1000 - Aluminized Silicone Coated Fiberglass Fabric

Rugged, Aluminized Silicone Coated Fiberglass, Up to 240 C

Material Sprcification: 1210

- Ideal for Automotive, Truck & Bus Applications

- Heat Reflective Silicone Coated Fiberglass

- Good Abraision Protection

- Custom Shapes Available

- Many Closures Available

SPECIFICATIONS

DESCRIPTION

SAM-1000 is a heavy weight; Silicone impregnated fiberglass fabric with a heat reflective Aluminum Foil surface laminated on one side with a high temperature adhesive. The combination makes SAM-1000 a flexible and durable heat protection jacket material with outstanding abrasion characteristics. SAM-1000 is best in moderate temperature heat barrier applications where a mechanically tough jacket is required. The material has a thermal effectiveness value of 69+°C when tested to SAE J2302 requirements. These characteristics make SAM-1000 an ideal choice for under hood applications in the Automotive, Truck and Bus industry. The material has an operational temperature range of -50°C to 240°C.

SAM-1000 - Aluminized Silicone Coated Fiberglass Fabric

Thermal Effectiveness