Overview

- Ideal for Aerospace Applications

- Excellent Abrasion, Environmental, Chemical & Electrical Properties

- Excellent Fluid Resistance

- Outstanding Flexibility & Abraison Resistance

- Flame Retardant

PFR-18 is an extremely flexible, flame-retardant polyether urethane material that has a soft rubber-like texture. PFR-18 jacketing offers exceptional ruggedness, resistance to abrasion and most fluids, while exhibiting high flexibility in virtually any demanding environment. The material meets Mil-I-3930/21 specifications and is an excellent choice for many nuclear, aerospace and military applications where PVC materials are not permitted. PFR-18 can be configured for round, flat and rectangular cable configurations and can be combined with most Zippertubing EMI Shielding materials.

Specifications

Similar Materials

|

|

|

|

| NAME | PFR-10 POLYURETHANE FILM - 10 MIL | PFR-8235 POLYURETHANE FILM WITH ADHESIVE BACKING | FSR-16 FLOURINATED SYNTHETIC RUBBER FILM - 16 MIL |

| DESCRIPTION | The most flexible, abrasion-resistant, polyurethane film, 10 Mil | Polyurethane Film w/ Adhesive backing, 7 Mil | Viton®, High Performance , Fluorinated Synthetic Rubber Film, 16 Mil |

| RoHS | RoHS-10 | RoHS-10 | RoHS-6 |

| Abrasion Resistance | Better | Better | |

| Min Temperature | Extreme | Extreme | Moderate |

| Minimum Operating Temperature | -67°F | -65°F | -20°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 225°F | 250°F | 392°F |

| Flexibility | Best | Best | |

| View | View | View |

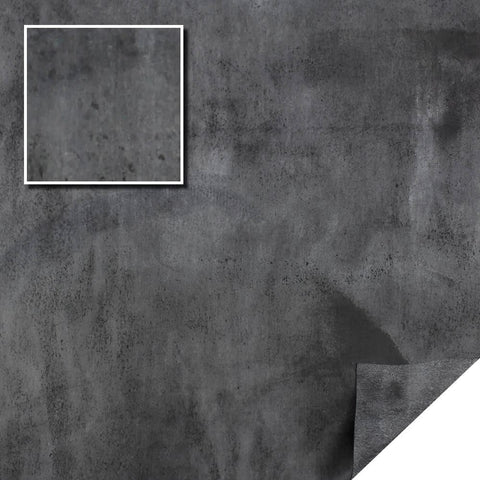

PFR-18 Polyurethane Film - 18 Mil

Extremely Flexible, Abrasion-Resistant, Polyurethane Film, 18 Mil

Material Sprcification: 1005

- Ideal for Aerospace Applications

- Excellent Abrasion, Environmental, Chemical & Electrical Properties

- Excellent Fluid Resistance

- Outstanding Flexibility & Abraison Resistance

- Flame Retardant

SPECIFICATIONS

DESCRIPTION

PFR-18 is an extremely flexible, flame-retardant polyether urethane material that has a soft rubber-like texture. PFR-18 jacketing offers exceptional ruggedness, resistance to abrasion and most fluids, while exhibiting high flexibility in virtually any demanding environment. The material meets Mil-I-3930/21 specifications and is an excellent choice for many nuclear, aerospace and military applications where PVC materials are not permitted. PFR-18 can be configured for round, flat and rectangular cable configurations and can be combined with most Zippertubing EMI Shielding materials.