Overview

- High Temperature Heat Reflective Fiberglass

- Good Fluid & Flame Resistance

- Ideal For Military & Aerospace Applications

- Round, Flat & Rectangular Shapes Available

- Many Closure Types Available

- -55 to 260°C Operating Limit

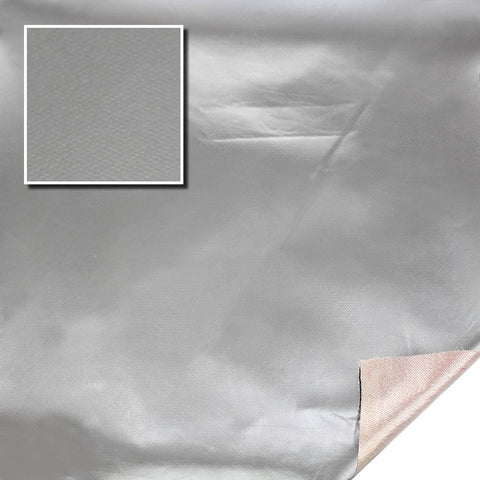

ALSR-15 is an extremely flexible, medium weight Silicone coated fiberglass cloth with a heat reflective Aluminized layer on one side that conforms to AMS-3673 formerly Mil-C-27347 and Naval Ordinance Specification 10001OS10591A. Designed to reflect over 90% of the thermal radiation from intense heat sources, this material makes an ideal high temperature jacketing system for electrical wires and cables. The Silicone rubber coating is fluid resistant, flame retardant and exhibits heat energy-absorbent properties which provide additional protection. ALSR-15 is ideal for high performance military and aerospace applications. The material has an operational temperature range of -55°C to 260°C.

Specifications

Thermal Effectiveness

Similar Materials

|

|

|

|

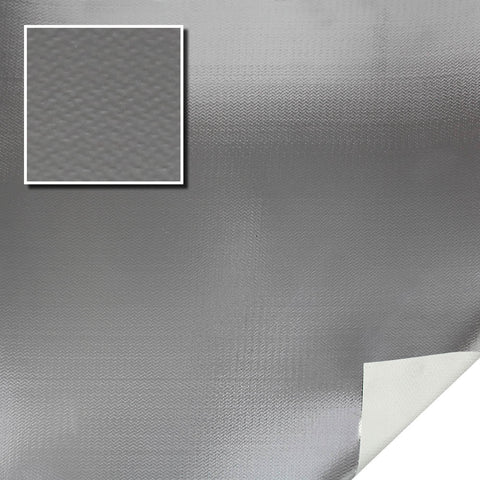

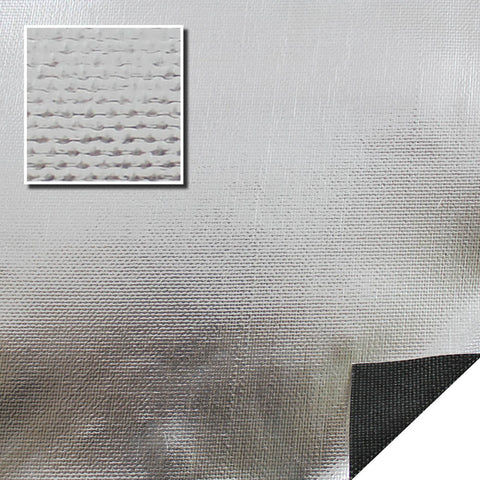

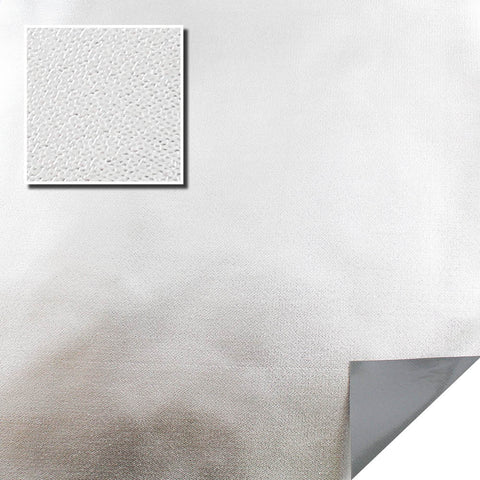

| NAME | ALS-5 FLEXIBLE ALUMINIZED FIBERGLASS HEAT SHIELDING | ALP-500 ALUMINIZED FIBERGLASS HEAT SHIELDING | SAM-1000 - ALUMINIZED SILICONE COATED FIBERGLASS FABRIC |

| DESCRIPTION | A thin, highly flexible aluminized fiberglass heat shielding material; shields up to 350°F (177°C). | Aluminized Fiberglass Heat Barrier, Up To 180°C | Rugged, Aluminized Silicone Coated Fiberglass, Up to 240 C |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Good | Best | Better |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -58°F | -58°F | -58°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 350°F | 350°F | 464°F |

| Flexibility | Best | Better | Better |

| View | View | View |

ALSR-15 Aluminized Silicone Coated Fiberglass

Mil-Spec Aluminized Silicone Coated Fiberglass, Up to 260°C

Material Sprcification: 1203

- High Temperature Heat Reflective Fiberglass

- Good Fluid & Flame Resistance

- Ideal For Military & Aerospace Applications

- Round, Flat & Rectangular Shapes Available

- Many Closure Types Available

SPECIFICATIONS

DESCRIPTION

ALSR-15 is an extremely flexible, medium weight Silicone coated fiberglass cloth with a heat reflective Aluminized layer on one side that conforms to AMS-3673 formerly Mil-C-27347 and Naval Ordinance Specification 10001OS10591A. Designed to reflect over 90% of the thermal radiation from intense heat sources, this material makes an ideal high temperature jacketing system for electrical wires and cables. The Silicone rubber coating is fluid resistant, flame retardant and exhibits heat energy-absorbent properties which provide additional protection. ALSR-15 is ideal for high performance military and aerospace applications. The material has an operational temperature range of -55°C to 260°C.

ALSR-15 Aluminized Silicone Coated Fiberglass

Thermal Effectiveness