Overview

- A highly flexible, easy-to-use EMI shielding knitted-mesh tape

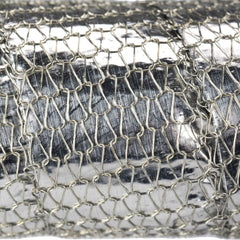

Zip-Mesh® (Al) is an EMI shielding tape that is versatile for any application. Made from a two-ply tinned copper mesh with an aluminum polyester tape and self-adhesive closure, Zip-Mesh® (Al) provides two shielding materials to protect your wires or cables from interferences. The aluminum foil is lightweight at only 0.002” thick, fluid resistant, and RoHS compliant. Zip-Mesh® (Al) is engineered to be the perfect fit for cable splices, branch-outs, and transitions to connector hardware; and it perfectly complements the Zippertubing’s SH1 foil and SHX series of knitted wire EMI shielding mesh.

Zip-Mesh® (Al) is offered in 1” and 2” tape widths with custom sizes available upon request. Zip-Mesh® (Al) has an operational temperature range of -40°F to 347°F (-40°C to 175°C).

Zip-Mesh® is also available as Zip-Mesh® (Cu), an EMI shielding mesh tape with a copper foil, or Zip-Mesh®, which is just the EMI shielding mesh in a tape roll. If you require a bit more flexibility, our Z-3250-Tape™ or Z-7200 Tape™ are ideal for high-flexing applications.

- Aluminum foil tape provides the best in EMI shielding materials

- Complements Zippertubing's SH1 foil and SHX series of knitted wire EMI shielding mesh

- Operational temperature range of -40°F to 300°F (-40°C to 149°C)

- Self-adhesive creates a secure seal around components

- Quick application that doesn't require any additional installation tools

- Wrap around any size wire or cable

Specifications

Overall Performance

- Closure:

- Flame Retardant:

- Thickness:

- Material Type:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

- Width:

Tape (High Temperature)

SH1 (Foil Shielding)

SHX-2 (SnCu)

Zip-Mesh® (Al)

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. |

| Closure | Tape (Electrically Conductive) | Adhesive | Adhesive |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Sleeve |

| Min Temperature | Moderate | Moderate | Extreme |

| Minimum Operating Temperature | °F | -49°F | -65°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 158°F | 250°F | 250°F |

| Flexibility | |||

| View | View | View |

Zip-Mesh® (Al) EMI Shielding Mesh Tape

An EMI shielding tape that has a tinned copper mesh with an aluminum polyester tape and a self-adhesive closure.

Drawing Number(s): ZT97-03-004

Selected Part Number: ZT97-03-004-1.0

Features

Benefits

Zip-Mesh® (Al) EMI Shielding Mesh Tape

SHIELDING EFFECTIVENESS - SH1 (Foil Shielding), SHX-2 (SnCu), Zip-Mesh® (Al)

Zip-Mesh® (Al) EMI Shielding Mesh Tape

MATERIAL SPECIFICATIONS