Overview

- Excellent high-frequency EMI, RFI and EMF shielding

- Ideal for minimal flexing applications

- Pressure-sensitive adhesvie closure

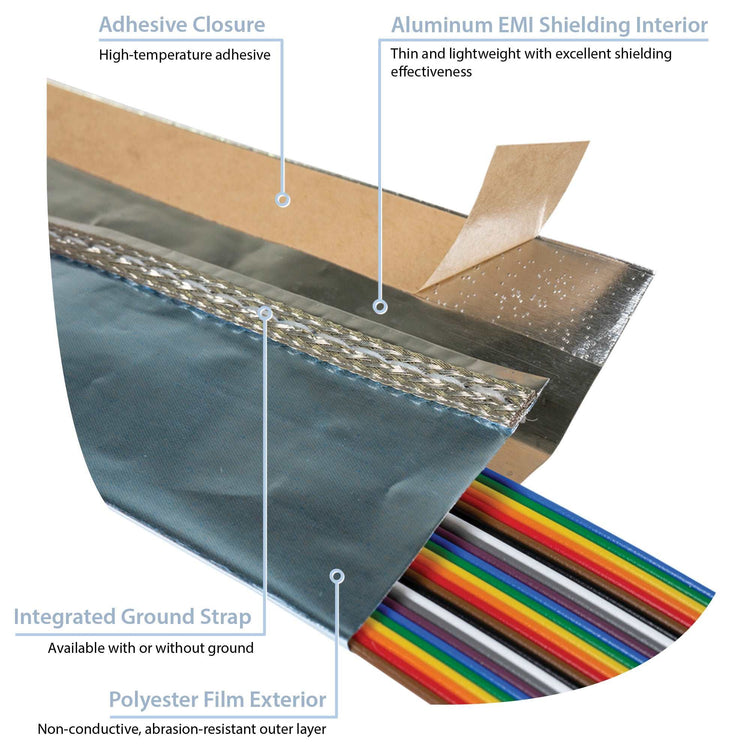

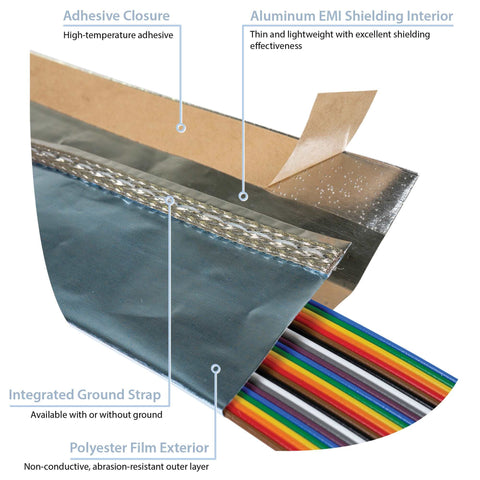

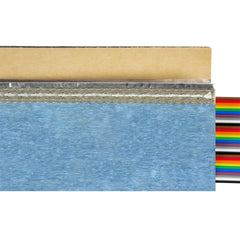

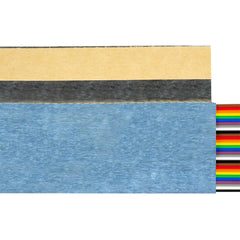

Z-Foil® is an EMI shielding solution made of a bright finished aluminum SH1 foil with a polyester film backing. The 0.001” thick aluminum foil is lightweight and resilient to foil breakup and pinholes. The shielding foil is perfect for high frequency EMI, RFI and EMF protection. The clear acrylic adhesive is flame retardant, solvent resistant and U.V. resistant. The adhesive provides a secure, long-lasting seal around wires or cables. An optional 15 AWG braided ground wire is also available for grounding capabilities.

Z-Foil® is the ideal solution for applications that will not experience flexing or movement, such as electronic racks. Z-Foil® is engineered for round or flat cables with diameters ranging from 0.25” to 4”; custom sizes are available upon request. The operational temperature range of Z-Foil® is -40°F to 300°F (-40°C to 149°C).

- SH1 Foil for shielding high frequency EMI, RFI and EMF interference

- Pressure-sensitive adhesive closure

- Operational temperature range of -40°F to 300°F (-40°C to 149°C)

- Clear acrylic adhesive is flame retardant, solvent resistant and U.V. resistant

- Grounding capabilities with optional 15 AWG braided ground strap

- Engineered for round or flat cables

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

Tape (High Temperature)

SH1 (Foil Shielding)

None

15 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. |

| Closure | Tape (Electrically Conductive) | Adhesive | Adhesive |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Sleeve |

| Min Temperature | Moderate | Moderate | Extreme |

| Minimum Operating Temperature | °F | -49°F | -65°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 158°F | 250°F | 250°F |

| Flexibility | |||

| View | View | View |

Z-Foil® Aluminum Foil EMI Shielding Wrap

Z-Foil® is a lightweight, high-performing EMI-shielding solution made of aluminum foil—equipped with a polyester film backing and adhesive closure.

Drawing Number(s): ZT03-04-011, ZT01-04-012, ZT03-04-008, ZT03-04-002

Selected Part Number: ZT03-04-011-0.25

Features

Benefits

Z-Foil® Aluminum Foil EMI Shielding Wrap

SHIELDING EFFECTIVENESS - SH1 (Foil Shielding)

Z-Foil® Aluminum Foil EMI Shielding Wrap

MATERIAL SPECIFICATIONS