Overview

- Double layer of EMI shielding cloth provides 99% shielding coverage

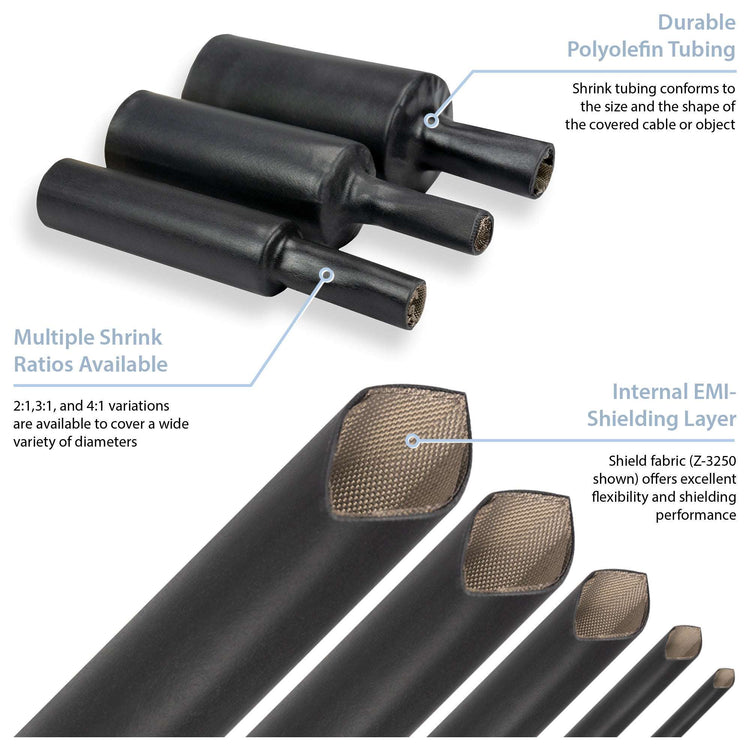

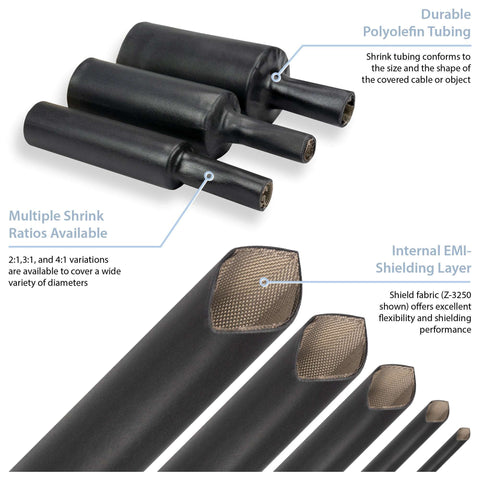

- MIL-SPEC polyolefin heat shrink tubing

- 2:1 shrink ratio offers versatility in application uses

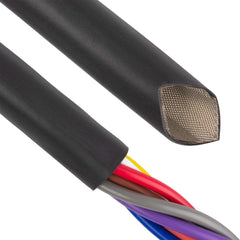

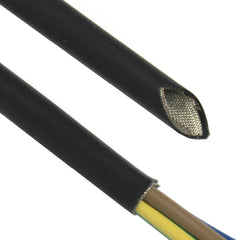

Shrink-N-Shield® (2X) is an EMI shielding heat shrink tubing that provides exceptional protection from EMI, RFI, and EMF. The MIL-SPEC heat shrink meets MIL-DTL-23053/5C, as well as being UL-rated with meeting UL224, VW-1, making this solution ideal for military and aerospace industries. The polyolefin tubing is flexible, abrasion resistant, and self-extinguishing. The heat shrink also has excellent fluid and fungus resistance to applications that are exposed to such elements. The 2:1 shrink ratio allows for versatile application uses, and the tubing allows for the ability to be cut to any desired length.

Shrink-N-Shield® (2X) is equipped with a double layer of EMI shielding cloth for exceptional protection. The Z-3250 shielding cloth is made of a taffeta fabric plated with copper then nickel for excellent corrosion protection. The lightweight, flexible shielding cloth will not flake or deteriorate over time, so you can be confident your components will have long-lasting protection against EMI, RFI, and EMF. The dual layer of Z-3250 provides 99% coverage for applications that desire more shielding than the standard EMI shielded heat shrink Zippertubing® manufactures.

Shrink-N-Shield® (2X) is offered for diameters ranging from 0.1875” to 1.5”, with custom sizes available upon request. The operational temperature range is -67°F to 275°F (-55°C to 135°C).

- Fluid resistant, fungus resistance, and abrasion resistant

- Shielding cloth is RoHS compliant and corrosion resistant

- Operational temperature range is -67°F to 275°F (-55°C to 135°C)

- Dual layer of Z-3250-CN shielding cloth for exceptional coverage

- Polyolefin tubing is military grade and UL-rated

- Can be easily cut to any desired length

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter - Before Shrink:

- Material:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shield Bonding:

- Shielding:

- Shielding Material:

- Shrink Ratio:

Polyolefin

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Typical Recovered Wall Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

Z-3250

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Guides

Shrink-N-Shield® (2X) EMI Shielded Heat Shrink Tubing

An EMI shielding solution that pairs polyolefin heat shrink with a dual layer of Z-3250-CN shielding cloth for applications requiring additional EMI shielding.

Drawing Number(s): ZT01-18-003

Selected Part Number: ZT01-18-003-0.1875-B-X48.0

Features

Benefits

Shrink-N-Shield® (2X) EMI Shielded Heat Shrink Tubing

SHIELDING EFFECTIVENESS - Z-3250

Shrink-N-Shield® (2X) EMI Shielded Heat Shrink Tubing

MATERIAL SPECIFICATIONS