Overview

- Abrasion and wear resistant outer jacketing material

- Withstands high heat and very low temperatures

- Highly flexible and can be combined with a variety of closure options

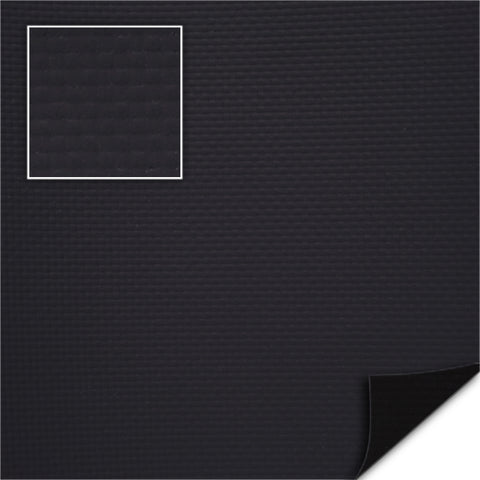

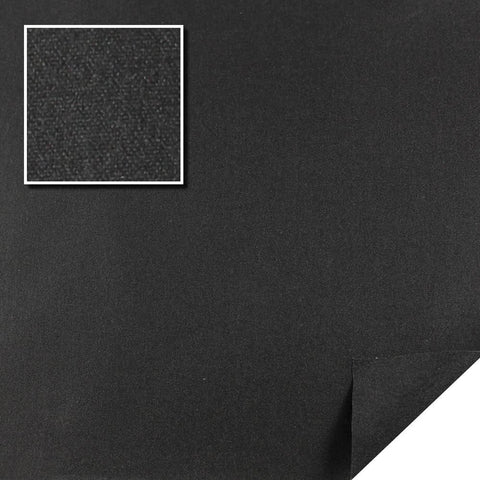

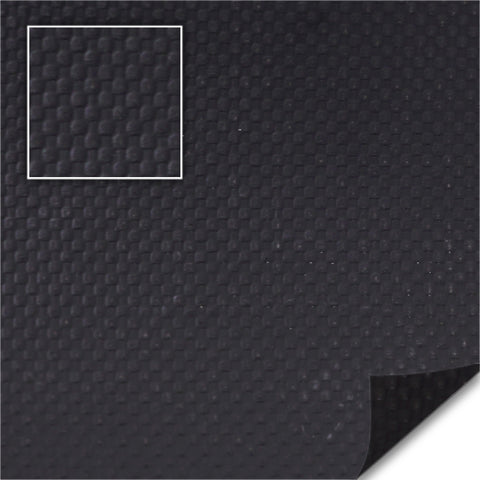

RPH-14 is the perfect material for creating an abrasion protection jacketing solution, that can withstand temperatures ranging from -67°F to 356°F. Unlike many other polyurethane compounds, RPH-14 is the most versatile in environments from one extreme to another. This material is a non-woven, pliable, and tear resistant fabric, allowing for a resilient solution in any harsh environment.

Polyester fabrics are extremely strong, allowing for the fabric to have high tensile strength and flexibility, as well as resistance against abrasion, mildew, and most organic solvents. RPH-14 is very similar to the basic structure of our RPU-17 material. The RPH-14 material is a dark-grey, medium weight, flame retardant polyurethane-coated polyester fabric, with a 0.014” thickness, allowing for a rugged, and flexible outer jacketing fabric solution.

Features

- Polyester base fabric with a polyurethane coating

- High-tear strength, of 15daN min. Warp and 10 daN min. Fill

- Temperature range of -67°F to 356°F

Benefits

- Medium weight, pliable, non-woven fabric

- Resistant to extreme temperatures, abrasion, and wear

- Can be combined with other materials and closures to create the perfect solution

Specifications

Similar Materials

|

|

|

|

| NAME | RPA-14 - POLYURETHANE COATED ARAMID FABRIC - 14 MIL | FRC-15 CANVAS FABRIC - 15 MIL | RPU-17 - HALOGEN-FREE POLYURETHANE COATED POLYESTER - 17 MIL |

| DESCRIPTION | A Strong, Medium-Weight, Polyurethane Coated Aramid Fabric | Lightweight Multi-Purpose Canvas Jacket, 15 Mil | Halogen-free Reinforced Polyurethane Cable Jacket |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Min Temperature | Low | Moderate | Moderate |

| Minimum Operating Temperature | -4°F | -22°F | -40°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 302°F | 140°F | 160°F |

| Flexibility | Better | ||

| View | View | View |

RPH-14 - Polyurethane Coated Polyester Fabric - 14 Mil

A Flexible, Medium Weight, Polyurethane Coated Polyester Fabric, 14 mil

Material Sprcification: 1132

- Abrasion and wear resistant outer jacketing material

- Withstands high heat and very low temperatures

- Highly flexible and can be combined with a variety of closure options

SPECIFICATIONS

DESCRIPTION

RPH-14 is the perfect material for creating an abrasion protection jacketing solution, that can withstand temperatures ranging from -67°F to 356°F. Unlike many other polyurethane compounds, RPH-14 is the most versatile in environments from one extreme to another. This material is a non-woven, pliable, and tear resistant fabric, allowing for a resilient solution in any harsh environment.

Polyester fabrics are extremely strong, allowing for the fabric to have high tensile strength and flexibility, as well as resistance against abrasion, mildew, and most organic solvents. RPH-14 is very similar to the basic structure of our RPU-17 material. The RPH-14 material is a dark-grey, medium weight, flame retardant polyurethane-coated polyester fabric, with a 0.014” thickness, allowing for a rugged, and flexible outer jacketing fabric solution.