Overview

- Ideal for Transportation and Automotive Heat Barrier Applications

- Custom Shapes and Closures Available

- Affordable High-Temperature Protection

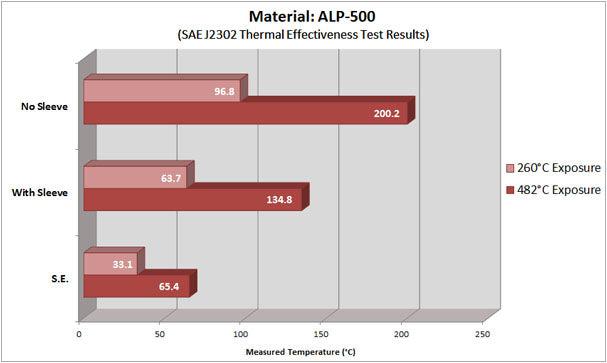

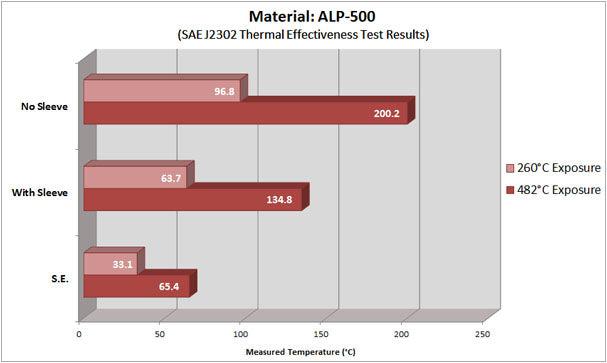

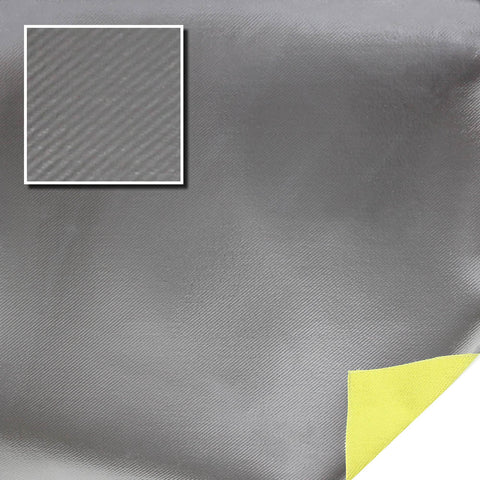

The ALP-500 material is a robust and flexible heat barrier solution, made from polyurethane-coated fiberglass with a reflective aluminum surface to block and dissipate radiant heat. Its versatility in size, shape, and closure options makes it an excellent choice for protecting electrical cables, hoses, and pipes in harsh, high-temperature environments. It offers reliable protection up to 180°C for sustained use, and up to 650°C for short burst exposure. ALP-500 offers significant thermal protection when tested per SAE J2302 standards for automotive heat barrier applications. This helps ensure dependable component performance in critical thermal environments like engine compartments and exhaust systems.

Specifications

Thermal Effectiveness

Similar Materials

|

|

|

|

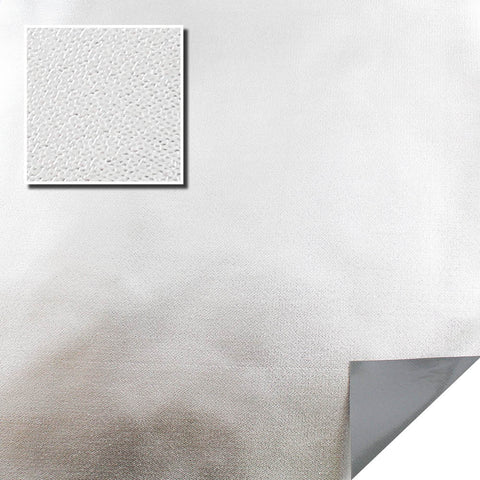

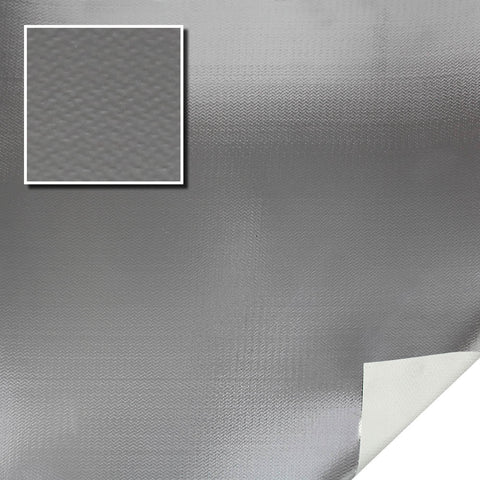

| NAME | ALS-5 FLEXIBLE ALUMINIZED FIBERGLASS HEAT SHIELDING | ALK-19 HEAT REFLECTIVE WOVEN KEVLAR FABRIC | ALSR-15 ALUMINIZED SILICONE COATED FIBERGLASS |

| DESCRIPTION | A thin, highly flexible aluminized fiberglass heat shielding material; shields up to 350°F (177°C). | High Strength Heat Reflective Woven Kevlar Fabric, Up to 177°C | Mil-Spec Aluminized Silicone Coated Fiberglass, Up to 260°C |

| RoHS | |||

| Abrasion Resistance | Good | Good | Better |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -58°F | -321°F | -67°F |

| Max Temperature | Moderate | Moderate | Extreme |

| Maximum Operating Temperature | 350°F | 350°F | 500°F |

| Flexibility | Best | Best | Best |

| View | View | View |

ALP-500 Aluminized Fiberglass Heat Shielding

Aluminized Fiberglass Heat Barrier, Up To 180°C

Material Sprcification: 1207

- Ideal for Transportation and Automotive Heat Barrier Applications

- Custom Shapes and Closures Available

- Affordable High-Temperature Protection

SPECIFICATIONS

DESCRIPTION

The ALP-500 material is a robust and flexible heat barrier solution, made from polyurethane-coated fiberglass with a reflective aluminum surface to block and dissipate radiant heat. Its versatility in size, shape, and closure options makes it an excellent choice for protecting electrical cables, hoses, and pipes in harsh, high-temperature environments. It offers reliable protection up to 180°C for sustained use, and up to 650°C for short burst exposure. ALP-500 offers significant thermal protection when tested per SAE J2302 standards for automotive heat barrier applications. This helps ensure dependable component performance in critical thermal environments like engine compartments and exhaust systems.

ALP-500 Aluminized Fiberglass Heat Shielding

Thermal Effectiveness