Overview

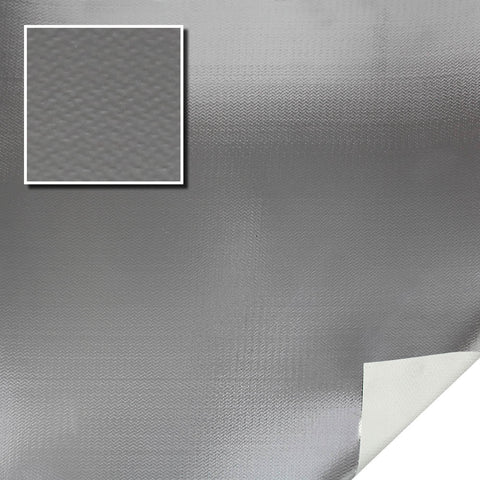

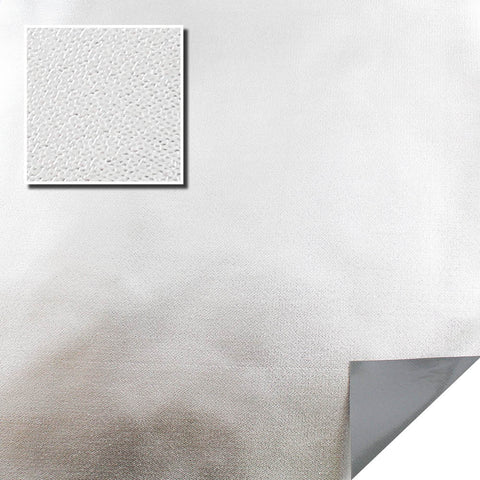

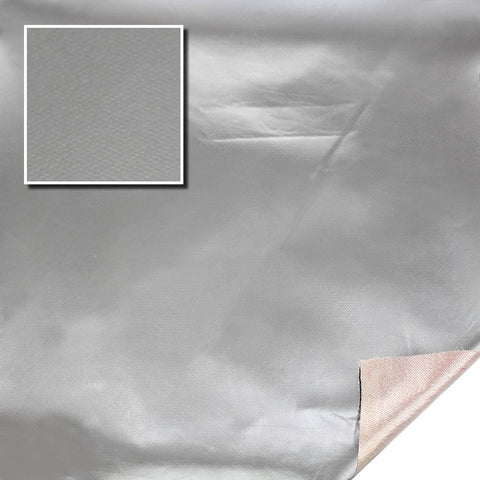

- Fiberglass cloth with reflective aluminum surface on one side

- Fire retardant and SAE tested for automotive applications

- Meets Mil-C-24929A

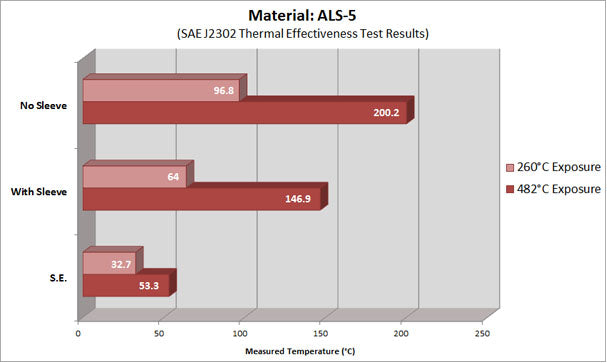

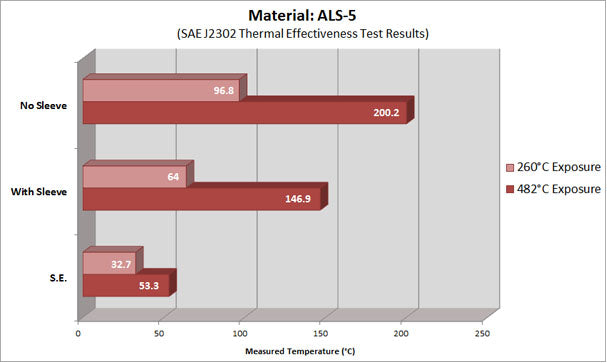

The ALS-5 material is highly flexible due to being only 0.006” thick, and engineered for smaller diameter components. The aluminized fiberglass cloth is intended for applications that are exposed to continuous temperatures as high as 350°F (177°C), with handling short bursts of temperatures as high as 572°F (300°C). The ALS-5 pairs well with an adhesive, high-temperature zipper, or Kevlar thread closure to provide complete, 360-degree heat shielding or custom components that need partial protection. ALS-5 works perfectly for automotive applications such as under-the-hood wiring because of the high-temperature capabilities, lightweight composition, and meeting the SAE J2302 requirements for Thermal Effectiveness.

Specifications

Thermal Effectiveness

Similar Materials

|

|

|

|

| NAME | ALP-500 ALUMINIZED FIBERGLASS HEAT SHIELDING | ALK-19 HEAT REFLECTIVE WOVEN KEVLAR FABRIC | ALSR-15 ALUMINIZED SILICONE COATED FIBERGLASS |

| DESCRIPTION | Aluminized Fiberglass Heat Barrier, Up To 180°C | High Strength Heat Reflective Woven Kevlar Fabric, Up to 177°C | Mil-Spec Aluminized Silicone Coated Fiberglass, Up to 260°C |

| RoHS | RoHS-10 | ||

| Abrasion Resistance | Best | Good | Better |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -58°F | -321°F | -67°F |

| Max Temperature | Moderate | Moderate | Extreme |

| Maximum Operating Temperature | 350°F | 350°F | 500°F |

| Flexibility | Better | Best | Best |

| View | View | View |

ALS-5 Flexible Aluminized Fiberglass Heat Shielding

A thin, highly flexible aluminized fiberglass heat shielding material; shields up to 350°F (177°C).

Material Sprcification: 1214

- Fiberglass cloth with reflective aluminum surface on one side

- Fire retardant and SAE tested for automotive applications

- Meets Mil-C-24929A

SPECIFICATIONS

DESCRIPTION

The ALS-5 material is highly flexible due to being only 0.006” thick, and engineered for smaller diameter components. The aluminized fiberglass cloth is intended for applications that are exposed to continuous temperatures as high as 350°F (177°C), with handling short bursts of temperatures as high as 572°F (300°C). The ALS-5 pairs well with an adhesive, high-temperature zipper, or Kevlar thread closure to provide complete, 360-degree heat shielding or custom components that need partial protection. ALS-5 works perfectly for automotive applications such as under-the-hood wiring because of the high-temperature capabilities, lightweight composition, and meeting the SAE J2302 requirements for Thermal Effectiveness.

ALS-5 Flexible Aluminized Fiberglass Heat Shielding

Thermal Effectiveness