Overview

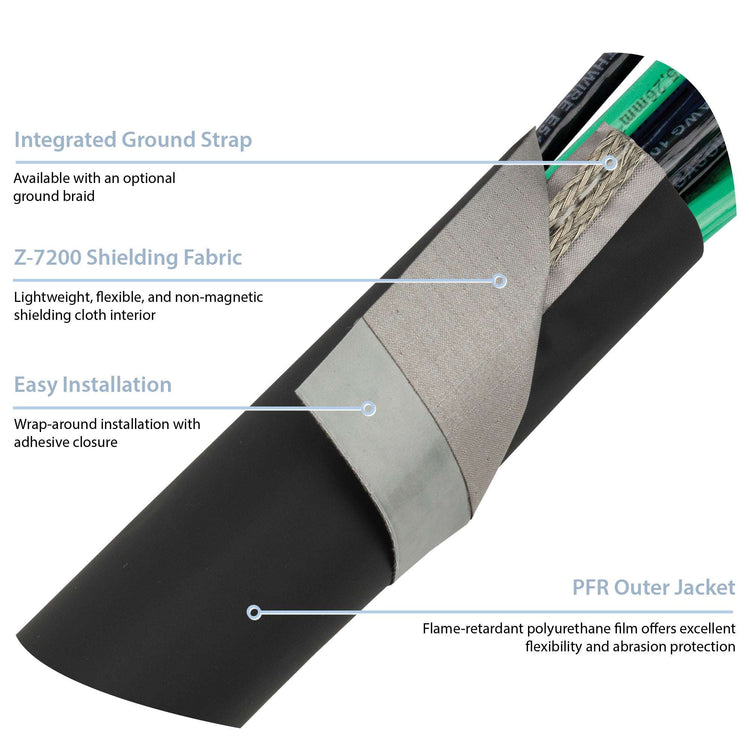

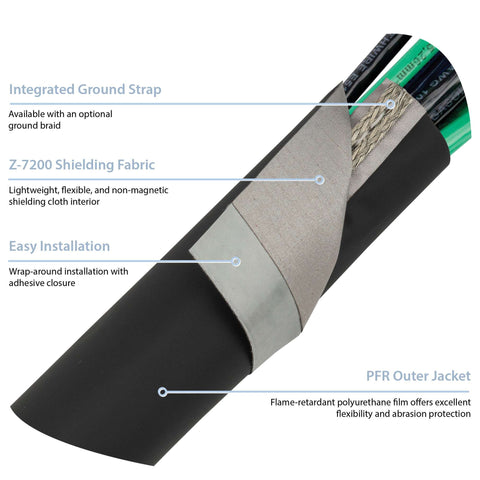

- Flame-retardant, abrasion-resistant, fluid-resistant, and chemical-resistant jacketing

- Pressure-sensitive adhesive with paper release liner for quick application

- No tools required for installation

Z-Shield® (7200) provides exceptional EMI, RFI, and EMF shielding while also providing durable jacketing to protect its components. The aromatic polyurethane film is resistant to abrasion, fluid, chemical, and UV exposure; it’s also flame retardant. Additionally, the jacketing has excellent dielectric strength and is flexible in both high and low temperature conditions.

The Z-7200 shielding cloth is made from a nylon rip stop fabric, plated with copper, and a proprietary corrosion- and fray-resistant coating. The cloth is nickel-free, halogen-free, and hypoallergenic for applications with those requirements. The 7200 shielding cloth also has the unique quality of being non-magnetic. Thus, making Z-Shield® (7200) the perfect choice for applications dealing with sensitive magnetic instrumentation. The 7200 shielding cloth will outlast harsh conditions; it won’t flake or rub off overtime. If required, a grounding wire can be incorporated into the solution for applications that may need to be burial. The grounding strap is a braided and flattened tin-plated copper wire.

Z-Shield® (7200) is engineered for component diameters ranging from 0.25” to 4”, with custom sizes available upon request. The operational temperature ranges from -40° to 250°F (UL rated up to 176°F).

- Non-magnetic, halogen-free, and hypoallergenic shielding cloth

- Excellent abrasion, fluid, chemical, and UV resistance

- Operational temperature ranges from -40°F to 250°F (UL rated up to 176°F)

- Wrap-around wires or cables with secure, permanent adhesive closure

- Provides 360° EMI, RFI, and EMF shielding

- Jacketing protects components with a non-PVC material makeup

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

PFR-8235

- Chemical Resistance:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

Z-7200

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. |

| Closure | Tape (Electrically Conductive) | Adhesive | Adhesive |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Sleeve |

| Min Temperature | Moderate | Moderate | Extreme |

| Minimum Operating Temperature | °F | -49°F | -65°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 158°F | 250°F | 250°F |

| Flexibility | |||

| View | View | View |

Guides

Z-Shield® (7200) EMI Shielding Wrap

A wrap-around solution that has a non-magnetic EMI shielding cloth and an adhesive closure.

Drawing Number(s):

Selected Part Number: ZT15-04-003-0.25-B

Features

Benefits

Z-Shield® (7200) EMI Shielding Wrap

SHIELDING EFFECTIVENESS - Z-7200

Z-Shield® (7200) EMI Shielding Wrap

MATERIAL SPECIFICATIONS