Overview

- A lightweight and extremely flexible non-PVC tape offered at an economical price

- UL510 recognized, flame retardant, and excellent in high-to-low temperatures

- Excellent for installations where cable splices, branch-outs and transitions are needed

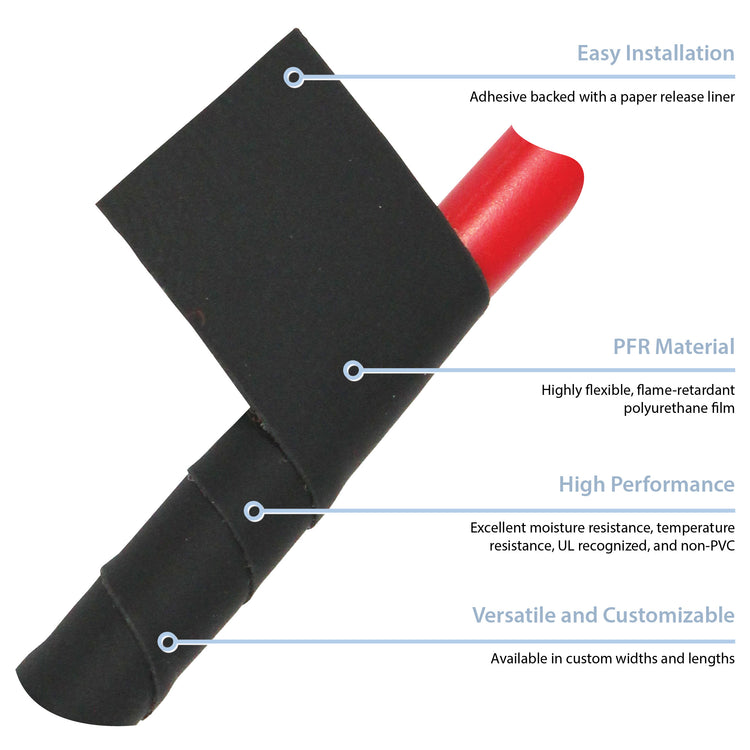

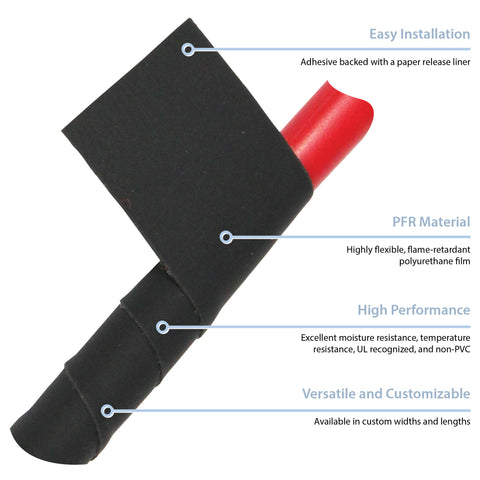

ZT-Tape® is a highly versatile, flexible, fire-resistant, non-PVC electrical tape that is made of a polyurethane film. With this tape’s pressure-sensitive acrylic adhesive backing, wires will be securely sealed from corrosion or abrasion. The adhesive uses a paper release liner for quick and easy application. Though ZT-Tape® is extremely secure, if there is ever a need to remove ZT-Tape®, no residue will be left behind, allowing for a clean removal. This high-quality electrical tape is an industry favorite due to its non-PVC, polyurethane jacketing, which makes ZT-Tape® ideal for environments that prohibit PVC material. This versatile cable and wire management solution revolutionizes traditional electrical tape and offers a superior substitute that will out-shine any traditional option for insulating and securing electrical wiring.

With its excellent protection from abrasion and its chemical and fire resistance, ZT-Tape® can be used in the most rugged environment or weather conditions. ZT-Tape® is UL510 recognized, and has an operating temperate range of -65°F to 250°F (-54°C to 121°C)*. Additionally, ZT-Tape® is UV-resistant for even more application possibilities.

ZT-Tape® is the solution for applications requiring high-quality, reliable, secure cable and wire management. ZT-Tape® is the electrical tape used in automotive industries due to its high temperature range, flexibility and exceptional dielectric strength.

** UL rated to 176°F (80°C)

- Fire-resistant, abrasion-resistant, chemical-resistant and UV-resistant

- Non-PVC, polyurethane jacketing that is ideal for environments that prohibit PVC material

- Easy installation with opportunities for cable splices, branch-outs and transitions

- Fits all wire and cable diameters

- Pressure-sensitive adhesive backing that provides complete security of wiring

- UL-rated, and has an operating temperate range of -65°F to 250°F (-54°C to 121°C)*

** UL rated to 176°F (80°C)

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Chemical Resistance:

- Closure:

- Dielectric Strength:

- Elongation:

- Material:

- Flame Retardant:

- Thickness:

- Thickness Variance:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Width:

- Tensile Strength:

- UV Resistance:

PFR-8235

- Chemical Resistance:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

ZT-Tape® Non-PVC Electrical Tape

A high-quality fire-resistant, abrasion-resistant and chemical-resistant electrical tape made of a non-PVC polyurethane film for insulation of wiring.

Drawing Number(s): ZT01-03-001

Selected Part Number: ZT01-03-001-1.0-B-X180.0

Features

Benefits

** UL rated to 176°F (80°C)

ZT-Tape® Non-PVC Electrical Tape

ZT-Tape® Non-PVC Electrical Tape

MATERIAL SPECIFICATIONS