Overview

- Flexible and flame-retardant polyurethane jacket

- EMI shielding fabric is non-magnetic

- Conductive adhesive closure with a paper release liner

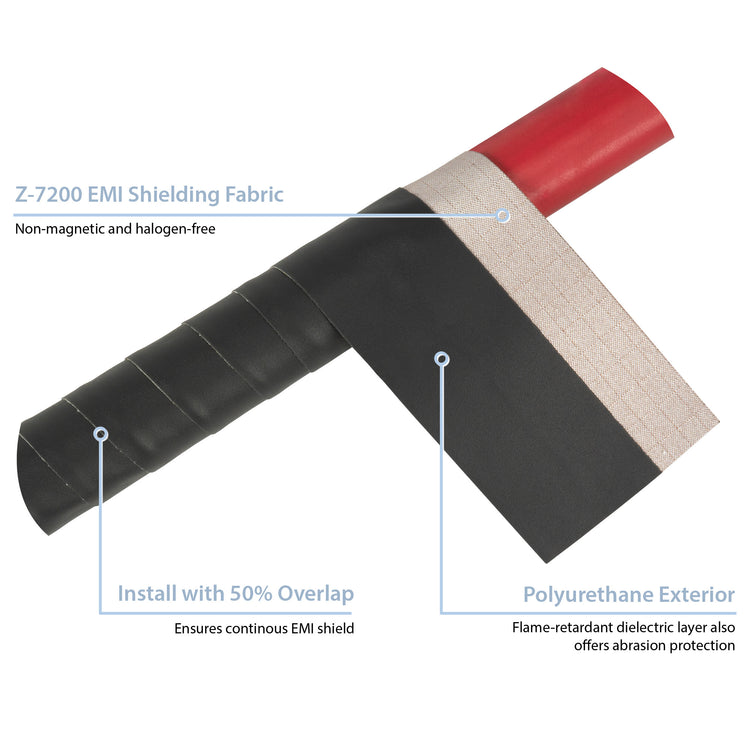

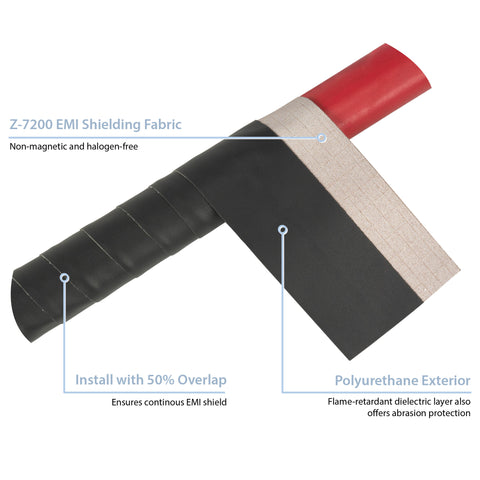

ZT-Shield® (7200) is an EMI shielding tape featuring a flame-retardant polyurethane jacket (ZT-Tape®) and conductive adhesive closure. The jacketing is a high quality, flexible, non-PVC electrical tape lined with our Z-7200 shielding fabric. ZT-Shield® (7200) offers excellent protection from abrasion, chemicals and flames—ideal for use in rugged environments and conditions. ZT-Shield® (7200) has non-PVC jacketing, which allows use on applications that prohibit PVC material.

The Z-7200 EMI shielding fabric is made of a copper-plated nylon rip-stop material with a proprietary, non-magnetic, corrosion-resistant coating. The 7200 shielding cloth is halogen-free and hypoallergenic for applications with such requirements. The conductive adhesive ensures a completely secure closure, and removes the possibility of any debris getting to the wires or cables.

When installed with a 50% overlap, ZT-Shield® (7200) provides the exceptional EMI, RFI and EMF shielding. For wire splits where cables are going in different directions, or when wires are so small that bulky jacketing would be too much, ZT-Shield® (7200) is the perfect solution for these unique applications. The durability, versatility, and having an operational temperature range of -58°F to 176°F (-50°C to 80°C) allows ZT-Shield® (7200) to be used for a variety industries and environments.

- Flame retardant, flexible, durable and lightweight jacketing

- Conductive adhesive backing and a paper release liner for easy application

- Operational temperatures ranging from -58°F to 176°F (-50°C to 80°C)

- High-quality EMI shielding tape for any wire, cable or component protecting needs

- Offered in standard sizes from 0.75” to 3” widths, with thinner and wider options available upon request

- Non-PVC material for applications with such requirements

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Chemical Resistance:

- Closure:

- Material:

- Flame Retardant:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Width:

- UV Resistance:

PFR-8235

- Chemical Resistance:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

Tape (Electrically Conductive)

Z-7200

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. |

| Closure | Tape (Electrically Conductive) | Adhesive | Adhesive |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Sleeve |

| Min Temperature | Moderate | Moderate | Extreme |

| Minimum Operating Temperature | °F | -49°F | -65°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 158°F | 250°F | 250°F |

| Flexibility | |||

| View | View | View |

ZT-Shield® (7200) EMI Shielding Tape

A durable EMI shielding tape paired with a non-magnetic shielding cloth—available in standard and custom width options for a variety of applications.

Drawing Number(s): ZT19-03-005

Selected Part Number: ZT19-03-005-0.75

Features

Benefits

ZT-Shield® (7200) EMI Shielding Tape

SHIELDING EFFECTIVENESS - Z-7200

ZT-Shield® (7200) EMI Shielding Tape

MATERIAL SPECIFICATIONS