Overview

- Flame Retardant, Mil-Spec Jacket

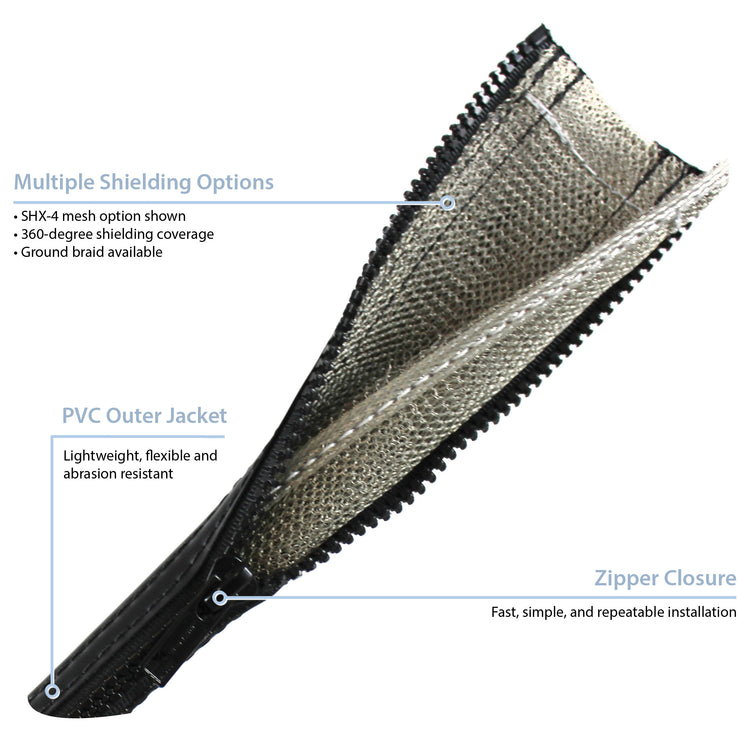

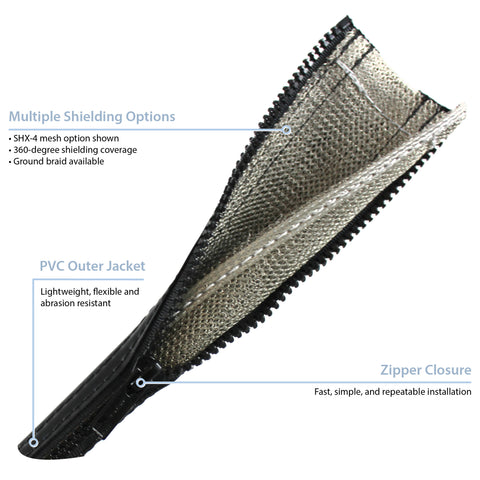

- Easy to install Zipper Closure

- Excellent Low Frequency EMI Shielding (500 KHz to 1 GHz)

- Ground Support & General Purpose Applications

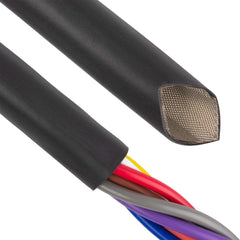

Zipper-Mesh™ (63) cable shielding is a convenient and efficient method of providing EMI/EMP protection to harnesses and wire bundles. It is a highly-flexible shield constructed of 4-ply knitted wire mesh utilizing an internal shield overlap, an integral grounding strap, and a heavy duty zipper closure. The zipper closure mechanism allows installation to be "tool-free", and re-entry to be very simple for cable repair or modification. The Mesh jacket is protected by a Mil-Spec, PVC jacket of flame retardant 63-20 film.

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

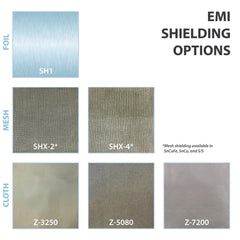

- Shielding:

- Shielding Material:

63-20

- Mil-Spec:

- REACH:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Elongation:

- Volume Resistivity:

- Flame Retardant:

- Fungicide:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Zipper (Nylon)

SHX-4 (SnCuFe)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Zipper-Mesh (63) Cable Bundling with EMI Shielding

SHX-4 EMI Shield, 63-20 Jacket, Zipper Closure

Drawing Number(s): ZT98-07-013

Selected Part Number: ZT98-07-013-0.5-B

Zipper-Mesh (63) Cable Bundling with EMI Shielding

SHIELDING EFFECTIVENESS - SHX-4 (SnCuFe)

Zipper-Mesh (63) Cable Bundling with EMI Shielding

MATERIAL SPECIFICATIONS