Overview

- Neoprene foam jacketing that provides a padded protective layer

- Insulates cables and protects against damage

- Available in many sizes, colors, and configurations

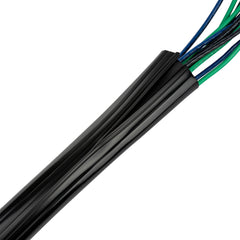

Zip-Wrap (NFN) is a re-enterable, zipper-closed sleeve built from neoprene foam faced with durable nylon fabric on both sides—the same comfortable, compliant construction you’d recognize from wetsuit materials. The wrap-around design installs in seconds without disconnecting cables, hoses, or lines, and the low-profile zipper keeps bundles tidy while allowing fast access for service or change-outs.

The neoprene foam jacketing helps insulate what it protects while adding a resilient buffer against everyday wear. It cushions against light impact and contact, helping prevent delicate surfaces from getting scratched, dinged, or dented, and the nylon facings provide a tough, snag-resistant exterior and interior that slide easily over bundles and hardware.

Zip-Wrap (NFN) is offered in multiple foam thicknesses, a wide range of diameters/lengths, and flexible color combinations to match your build or visual management scheme. Choose the thickness to balance cushioning and flexibility, pick your size for a neat, secure fit, zip it closed—and you’re done with a clean, professional-looking protective jacket that’s easy to install and even easier to reopen when needed.

- Zipper-closed, re-enterable sleeve—install or reopen without disconnecting cables/hoses

- Neoprene foam with dual-sided nylon facings for durability and smooth handling

- Offered in multiple foam thicknesses, sizes, and color combinations

- Provides insulation and vibration damping to protect sensitive lines and maintain performance

- Cushions against light impact and contact, helping prevent scratches, dings, and dents

- Flexible with stretch to fit large or irregularly shaped components

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

NFN – Neoprene foam with Nylon fabric

- REACH:

- Humidity Resistance:

- Chemical Resistance:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

Zipper (Nylon)

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Zip-Wrap (NFN) Protective Foam Sleeving

Wrap-around cable jacketing made from resilient neoprene foam and a zipper closure.

Drawing Number(s): ZT25-07-004

Selected Part Number: ZT25-07-004-0.5-B-B

Features

Benefits

Zip-Wrap (NFN) Protective Foam Sleeving

Zip-Wrap (NFN) Protective Foam Sleeving

MATERIAL SPECIFICATIONS