Overview

- Jacketing is abrasion resistant, chemical resistant, U.V. resistant, and fire retardant

- Shielding fabric is coated with copper and nickel for excellent corrosion resistance

- Wrap-around solution can be installed in the production environment without disconnecting or re-wiring of components

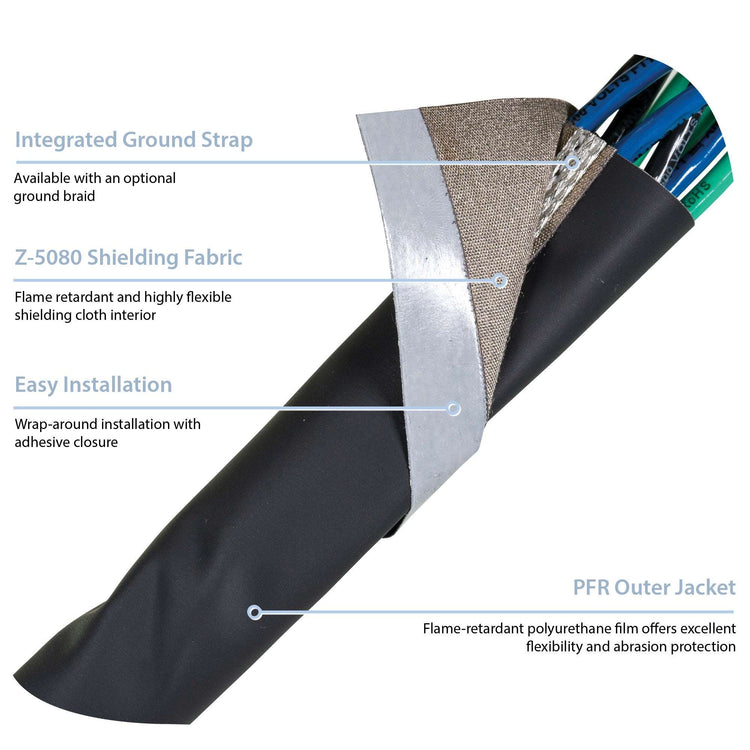

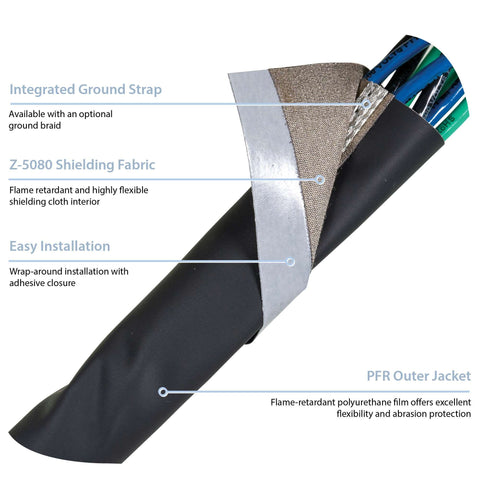

Z-Shield® (5080) is a wrap around EMI shielded jacket made of fire-retardant Polyurethane film, flame retardant Z-5080 EMI shielding cloth, and an adhesive closure. This combination provides good electromagnetic shielding of wires and cables in applications requiring outstanding flexibility, flammability to UL224, VW-1, and good dielectric strength.

This product is extremely useful in electronics applications where space may require a thin and flexible shielding. Z-Shield® (5080) can be configured to fit most Round, Flat or Rectangular cable configurations and is available with or without a drain wire installed.

This product has an operational temperature range of -22°F to 248°F (-30°C to 120°C).

- Z-5080 shielding cloth provides better EMI shielding

- Adhesive provides permanent, long-lasting closure

- Operational temperature range of -22°F to 248°F (-30°C to 120°C)

- Can be cut to any desired length for versatility of application uses

- PFR-8235 jacketing withstands rugged environmental conditions

- Installation does not require disassembly of wires or cables

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Flammability:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

PFR-8235

- Chemical Resistance:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

Z-5080

Nylon Thread

None

15 AWG Braided Ground Straps

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. |

| Closure | Tape (Electrically Conductive) | Adhesive | Adhesive |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Sleeve |

| Min Temperature | Moderate | Moderate | Extreme |

| Minimum Operating Temperature | °F | -49°F | -65°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 158°F | 250°F | 250°F |

| Flexibility | |||

| View | View | View |

Guides

Z-Shield® (5080) EMI Shielding Wrap

Fire-Retardant Polyurethane Jacket with Z-5080 EMI Shield

Drawing Number(s): ZT97-04-031, ZT98-04-011, ZT97-04-035, ZT98-04-018

Selected Part Number: ZT97-04-031-0.25-B

Features

Benefits

Z-Shield® (5080) EMI Shielding Wrap

SHIELDING EFFECTIVENESS - Z-5080

Z-Shield® (5080) EMI Shielding Wrap

MATERIAL SPECIFICATIONS