Overview

- Self-closing EMI sleeve requires no tools for installation

- Flexible and lightweight PET material

- EMI shielding cloth protects against damaging interferences

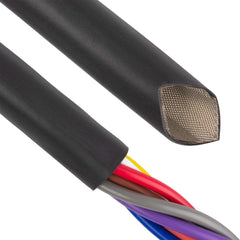

Z-Coil™ (3250) is a cost-effective cable management solution for applications requiring EMI shielding and the protection of wires and cables. The self-closing, wrap-around sleeve is easy to use and configure for any cable- or wire-bundling job. The material is woven from polyester (PET), is flexible, and naturally coils into itself. The jacketing is resistant to chemicals, mildew, and fungus. Additionally, the jacketing is RoHS compliant, provides good abrasion protection, and is self-extinguishing and halogen-free. This multifunctional cable management solution is perfect for environments that may experience high temperatures, with the operational temperature ranging from -58 °F to 302 °F.

The 3250-CN EMI-shielding fabric is 0.004” thick and made of a flexible, lightweight, polyester taffeta material. The shielding material is plated with copper and then coated with nickel for corrosion protection. This thin yet durable EMI shielding fabric is also resistant to environmental degradation, making this solution ideal for applications that may be exposed to rugged conditions.

Z-Coil™ (3250) is ideal for both the after-market restoration and high-production automotive manufacturing industries due to its quick and easy installation around wires and cables, its superior abrasion resistance, and its broad temperature range. The EMI shielding property also protects any wires or cables from being compromised by exposure to EMI. As electromagnetic frequencies are continually growing as a result of the high demand for additional electrical equipment, Z-Coil™ (3250) solves both wire-bundling and EMI shielding issues at an economical price.

Z-Coil™ (3250) offers a set of standard diameter sizes: 0.1875”, 0.375”, 0.5", 0.75”, and 1.0", with custom diameters available upon request. The operational temperature range is -40°F to 250°F (-40°C to 121°C).

- PET jacketing for protection against abrasion and environmental degradation

- Z-3250 shielding cloth to protect components from EMI, RFI and EMF

- Operating temperature range of -58 °F to 302 °F (-50 °C to 150 °C)

- Self-closing, wrap-around wire sleeve requires no tools for quick installation

- Resistant to chemicals, mildew, and fungus

- Self-extinguishing

Specifications

Overall Performance

- Cable Diameter:

- Chemical Resistance:

- Closure:

- Material:

- Flammability:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shielding:

Polyester (PET)

- REACH:

- Chemical Resistance:

- Flammability:

- Mildew/Fungus Resistance:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

Z-3250

Nylon Thread

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Z-Coil (3250) Self-Closing Jacketing with EMI Shielding

A self-closing, wrap-around wire bundling and protection sleeve with EMI shielding.

Drawing Number(s): ZT19-19-001

Selected Part Number: ZT19-19-001-0.375

Features

Benefits

Z-Coil (3250) Self-Closing Jacketing with EMI Shielding

SHIELDING EFFECTIVENESS - Z-3250

Z-Coil (3250) Self-Closing Jacketing with EMI Shielding

MATERIAL SPECIFICATIONS