Overview

- Corrosion and fray resistant shielding cloth

- Conductive adhesive closure with paper release liner

- Non-magnetic, nickel-free, halogen-free, and hypoallergenic

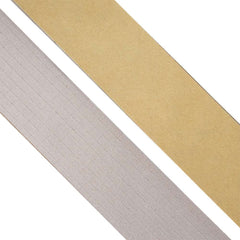

Our Z-7200-Tape™ is a lightweight and flexible EMI shielding tape. The Z-7200-Tape™ is RoHS Compliant, and durable in that it will not flake off over time. The shielding cloth is 0.005” thick and is made of a smooth, nylon rip-stop fabric that is plated with copper and a proprietary corrosion and fray resistant coating. This electrical shielding tape is also nickel-free and won’t cause skin irritation like typical nickel products can. The conductive adhesive securely fastens around wires and cables for a strong closure. When installed with a 50% overlap, Z-7200-Tape™ offers exceptional EMI, RFI, and EMF protection.

The Z-7200-Tape™ is non-magnetic, which is necessary in EMI hardening components of sensitive GPS navigation systems and earthquake monitoring equipment that can be easily upset with nearby magnetic material. The shielding attenuation levels average 60dB from 10MHz to 18GHz, providing exceptional protection against interferences that can compromise valuable component systems.

Our Z-7200-Tape™ is versatile, and can be utilized with a variety of Zippertubing® solutions to protect from EMI, RFI, and EMF. With an operational temperature range from -40°F to 302°F (-40°C to 150°C), Z-7200-Tape™ can withstand higher temperatures for a variety of environments and conditions.

- Conductive adhesive creates a secure closure around wires and cables

- Standard sizes offered, as well as custom widths available upon request

- Operational temperature of 158°F (70°C)

- Offers EMI, RFI, and EMF shielding without containing nickel

- Lightweight and flexible shielding cloth that is corrosion and fray resistant

- Halogen-free and hypoallergenic for applications with such requirements

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Closure:

- Elongation:

- Halogen Free:

- Thickness:

- Maximum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

- Width:

Tape (Electrically Conductive)

Z-7200

Similar products

|

|

|

|

| NAME | Z-3250-TAPE EMI SHIELDING TAPE | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP |

| DESCRIPTION | A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications. | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. |

| Closure | Tape (Electrically Conductive) | Adhesive | Adhesive |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Tape | Sleeve | Sleeve |

| Min Temperature | Moderate | Moderate | Extreme |

| Minimum Operating Temperature | °F | -49°F | -65°F |

| Max Temperature | Moderate | Low | Low |

| Maximum Operating Temperature | 158°F | 250°F | 250°F |

| Flexibility | |||

| View | View | View |

Z-7200-Tape EMI Shielding Tape

An EMI shielding tape that is non-magnetic, halogen-free, and hypoallergenic.

Drawing Number(s): ZT20-03-001

Selected Part Number: ZT20-03-001-*

Features

Benefits

Z-7200-Tape EMI Shielding Tape

SHIELDING EFFECTIVENESS - Z-7200

Z-7200-Tape EMI Shielding Tape

MATERIAL SPECIFICATIONS