Overview

- Extremely thin, flexible and lightweight

- Shield coverage > 98%

- Conductive-adhesive backing

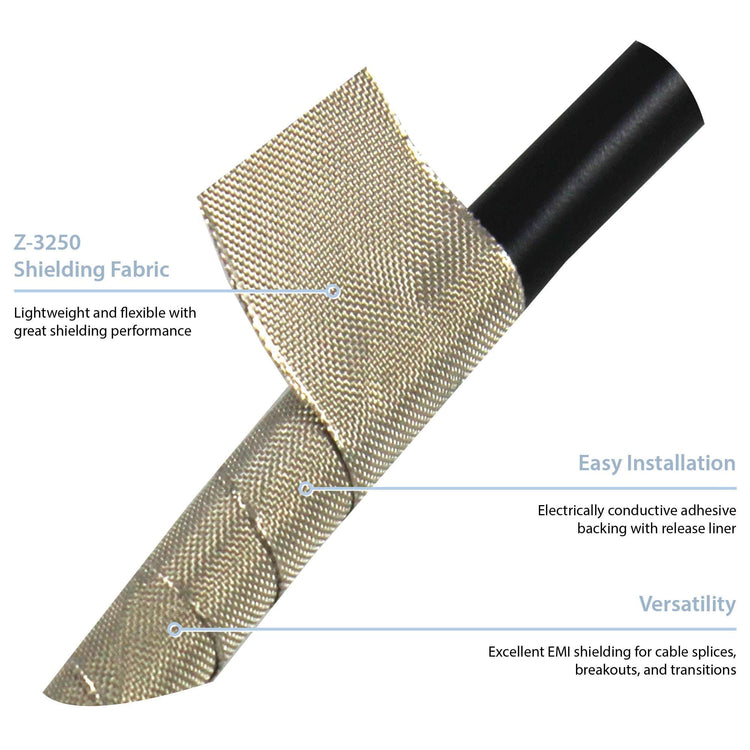

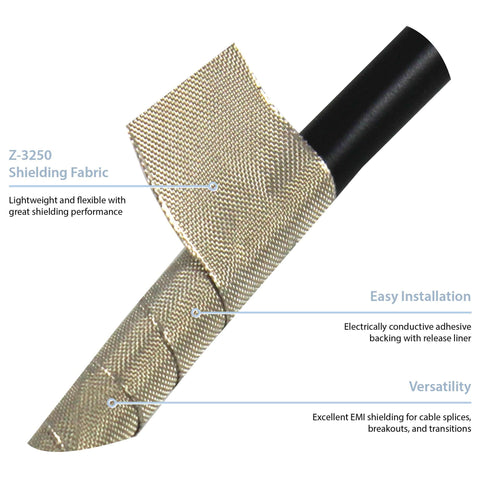

Z-3250-Tape™ is a Zippertubing®-favorite solution. This EMI, RFI and EMF shielding tape is one of the most versatile products offered. Having a corrosion resistant coating made of plated copper and nickel, Z-3250-Tape™ can be used in rugged environments. The polyester taffeta cloth is lightweight, flexible, and doesn’t flake with time. This electrical shielding tape has a conductive adhesive with a paper release liner, allowing for easy and clean application. The secure adhesive closure creates a complete electrical shielding enclosure around any wire or cable.

Z-3250-Tape™ is the choice for shielding cable splices, wire connectors, or branch-outs from EMI, RFI and EMF. When installed with a 50% overlap, this product will accomplish a 98% shielding coverage, ensuring your wires and cables will not be compromised by damaging electromagnetic interferences.

Z-3250-Tape™ is offered in standard 1” and 2” widths, with custom thinner or wider options available upon request. The operational temperature of Z-3250-Tape™ is 158°F (70°C).

If you are looking for a halogen-free, non-magnetic version of this tape, we offer our Z-7200-C EMI shielding cloth. Contact us to find out other available options.

- Easy installation with no tools required

- Standard sizes offered, as well as custom widths available upon request

- Operational temperature of 158°F (70°C)

- Offers exceptional EMI, RFI and EMF protection

- Conductive adhesive creates an electrical shielding enclosure around wires and cables

- Corrosion-resistant coating allows for use on applications in a variety of environments

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Closure:

- Thickness:

- Maximum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

- Width:

- Weight :

Tape (Electrically Conductive)

Z-3250

Similar products

|

|

|

|

| NAME | Z-SHIELD® (3250) EMI SHIELDING WRAP | Z-SHIELD® (AL) EMI SHIELDING WRAP | ZIP-MESH® (AL) EMI SHIELDING MESH TAPE |

| DESCRIPTION | A wrap-around solution that has a protective jacketing paired with an EMI shielding cloth and adhesive closure. | A wrap-around, EMI-shielding solution featuring a flame-retardant polyurethane jacket and high-performing shielding foil. | An EMI shielding tape that has a tinned copper mesh with an aluminum polyester tape and a self-adhesive closure. |

| Closure | Adhesive | Adhesive | Tape (High Temperature) |

| RoHS | RoHS-10 | RoHS-10 | RoHS-6 |

| Abrasion Resistance | |||

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Tape |

| Min Temperature | Moderate | Extreme | Moderate |

| Minimum Operating Temperature | -49°F | -65°F | -40°F |

| Max Temperature | Low | Low | Moderate |

| Maximum Operating Temperature | 250°F | 250°F | 300°F |

| Flexibility | |||

| View | View | View |

Z-3250-Tape EMI Shielding Tape

A lightweight EMI shielding tape that is flexible, durable and corrosion resistant for a variety of applications.

Drawing Number(s): ZT93-03-003

Selected Part Number: ZT93-03-003-1.0

Features

Benefits

Z-3250-Tape EMI Shielding Tape

SHIELDING EFFECTIVENESS - Z-3250

Z-3250-Tape EMI Shielding Tape

MATERIAL SPECIFICATIONS