Overview

- Abrasion-resistant, fluid-resistant, and fungus-resistant polyolefin

- Offers superior component repair or a secondary insulation jacket

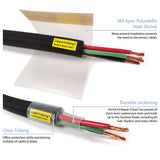

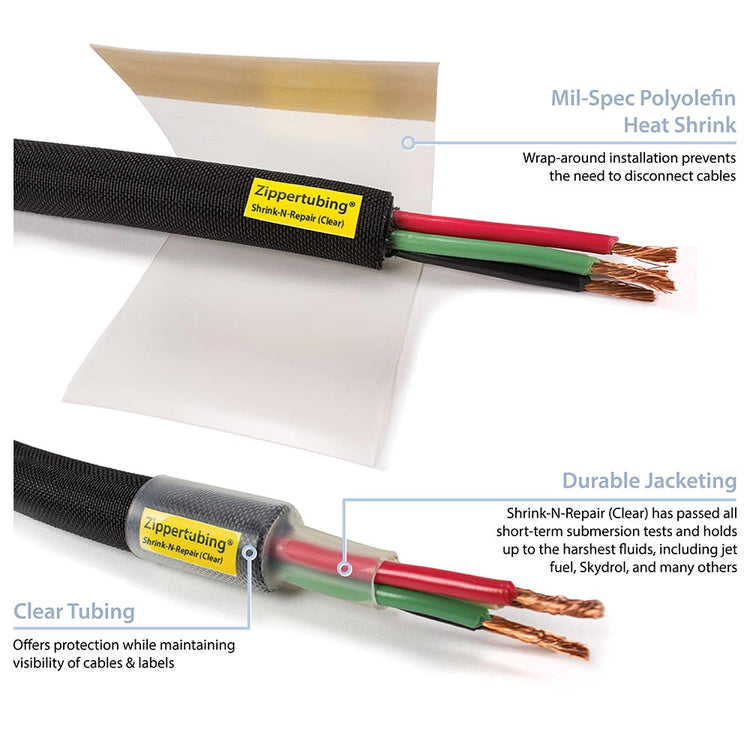

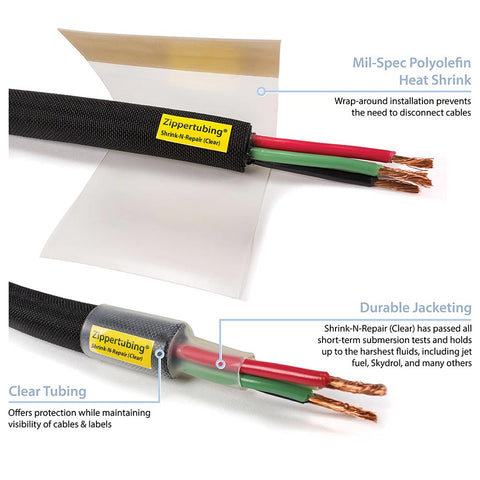

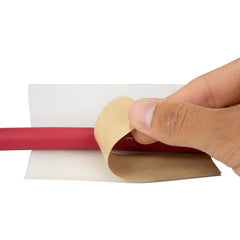

- Wrap-around split heat shrink allows for installation without disconnection or disassembly

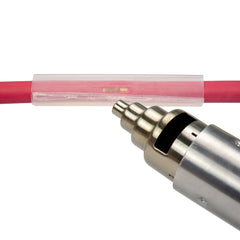

Shrink-N-Repair (Clear) is an innovative wrap around heat shrink tubing solution designed for efficient cable repair and protection without the need to disconnect or disassemble existing wiring. This transparent material ensures that labels and wire markings remain visible, making it perfect for industries where precise identification is essential, such as aerospace, automotive, and electronics. Its 2:1 shrink ratio guarantees a snug, secure fit over a wide range of cables, providing both insulation and protection against environmental factors like abrasion, moisture, and chemical exposure.

Material Composition:

The clear polyolefin construction offers a superior balance of durability and flexibility. It withstands extreme temperatures and environmental conditions, ensuring long-lasting performance even in harsh industrial applications.

Easy Installation:

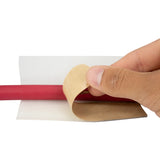

Featuring a self-adhesive backing with a paper release liner, Shrink-N-Repair (Clear) allows for quick and clean installation. Simply wrap it around the damaged or exposed section of the cable, heat it to shrink, and it will form a tight seal that protects against further damage while allowing visual inspection of the cable beneath.

This product is ideal for customers needing a quick, effective, and visually transparent solution for cable management and repair in challenging environments.

- Wrap-Around Design: No need to disconnect cables, reducing downtime and labor costs.

- Transparency: Unlike opaque shrink solutions, Shrink-N-Repair (Clear) maintains the visibility of wire labels and markings, which is critical in applications requiring regular inspection and troubleshooting.

- Abrasion and Chemical Resistance: Engineered to withstand harsh environments, including exposure to fuels, oils, and other chemicals, this product ensures the longevity of the repair.

- Fluid Resistance: Resistant to jet fuel, Skydrol, hydraulic fluid, and other chemicals.

- Can be cut to desired length: Customizable to meet various cable lengths.

- Better than traditional heat shrink: Due to its wrap-around capabilities, it provides easier application without needing to disconnect or dismantle wiring systems.

Specifications

Overall Performance

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shrink Ratio:

Clear Polyolefin Heat Shrink Tubing

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

Tape (Specialty Surface)

Similar products

|

|

|

|

| NAME | PRT® MIL-SPEC WRAP-AROUND HEAT SHRINK TUBING | SHRINK-N-REPAIR® (M) WRAP-AROUND HEAT SHRINK | PRT® (ES-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK |

| DESCRIPTION | A wrap-around heat shrink made from MIL-SPEC tubing that repairs electrical systems and assembled components and is resistant to abrasion and chemicals. | A wrap-around, abrasion-resistant, fluid-resistant heat shrink that repairs wires or cables with diameters up to 0.5”. | A wrap-around, military-grade heat shrink paired with a high-temperature water blocking, hot-melt adhesive that protects against harsh environmental conditions. |

| Closure | Tape (Specialty Surface) | Tape (Specialty Surface) | Tape (Specialty Surface) |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Best |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Wire Repair | Wire Repair | Water Blocking |

| Min Temperature | Extreme | Moderate | Extreme |

| Minimum Operating Temperature | -67°F | -67°F | -67°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 275°F | 275°F | 275°F |

| Flexibility | |||

| View | View | View |

Shrink-N-Repair (Clear) Polyolefin Heat Shrink

A clear, polyolefin 2:1 wrap around heat shrink tubing ideal for applications requiring a durable repair solution while maintaining full visibility of wire labels for easy identification and inspection.

Drawing Number(s):

Selected Part Number: RP-ZT23-04-008-C-X12.0

Features

Benefits

Shrink-N-Repair (Clear) Polyolefin Heat Shrink

Shrink-N-Repair (Clear) Polyolefin Heat Shrink

MATERIAL SPECIFICATIONS