Overview

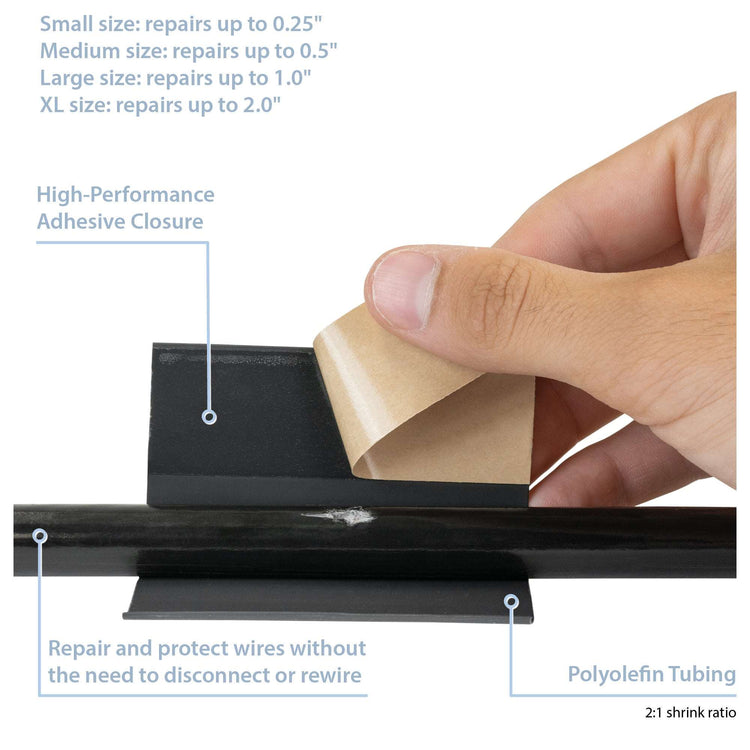

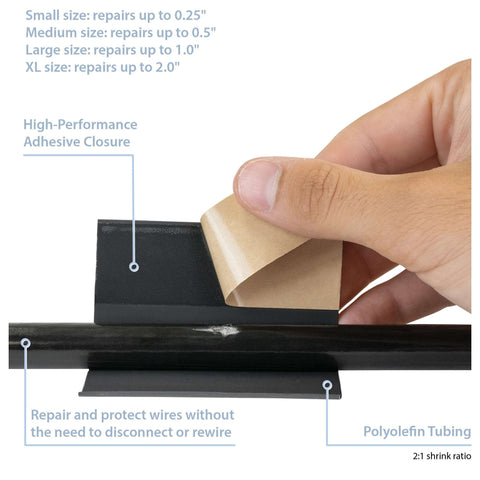

- Repairs and protects wires without disconnection or re-wiring

- Abrasion-resistant and fluid-resistant polyolefin tubing

- Available in custom lengths and colors, subject to minimum order quantity (MOQ) requirements.

Shrink-N-Repair® is a wrap-around heat shrink for damaged, cracked, or chafed components that need a quick repair without downtime or disconnection. Shrink-N-Repair® is unlike other heat shrink tubing because it can be wrapped lengthwise around the wire or cable. Typical heat shrink is a sleeve that requires disassembly and more resources, whereas Shrink-N-Repair® can be installed with only a heat gun and a standard pair of scissors. The polyolefin 2:1 heat shrink is abrasion resistant, fluid resistant, and fungus resistant, as well as flame retardant. The clear acrylic-based transfer adhesive tape provides a secure bond that withstands high-heat shock. Additionally, the adhesive is equipped with a paper release liner for quick and easy application.

Shrink-N-Repair® has an operational temperature range of -67°F to 275°F (-55°C to 135°C).

If you require a wrap-around heat shrink for diameters as small as 0.05”, we also offer Shrink-N-Repair® (Thin). This version is engineered for diameters of 0.05” to 0.25”. And if you require a wrap-around heat shrink for diameters of 0.5” to 1”, we offer Shrink-N-Repair® (L), as well as Shrink-N-Repair® (XL) for diameters as large as 2”.

If your application requires a more rugged heat shrink, we offer PRT®, our MIL-SPEC, UL-rated, wrap-around heat shrink for diameters up to 1.87”. PRT® also has combinations for applications requiring EMI shielding and/or water blocking, as well as custom combinations available upon request.

- Better than traditional heat shrink due to wrap-around capabilities

- Save time and resources by never needing to disconnect or disassemble

- Available in different colors and lengths

- Resistant to most oils, fluids, mild acids, and alkalis

- One size fits most repairs up to 0.5” in diameter

- Re-sealable container to improve shelf life and longevity of the product

Specifications

Overall Performance

- Closure:

- Dielectric Strength:

- Elongation:

- Material:

- Flammability:

- Fungicide:

- Heat Shrink Material:

- Longitudinal Shrinkage:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shrink Ratio:

- Shrink Temperature:

Polyolefin

- Mil-Spec:

- REACH:

- Dielectric Strength:

- Elongation:

- Flammability:

- Fungicide:

- Longitudinal Shrinkage:

- Material:

- Typical Recovered Wall Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

- Specific Gravity:

- Outgasssing (%TML):

- Outgassing (%CVCM):

- Outgassing (%WVR):

Tape (Specialty Surface)

Similar products

|

|

||

| NAME | PRT® MIL-SPEC WRAP-AROUND HEAT SHRINK TUBING | PRT® (ES-135) WATER-BLOCKING WRAP-AROUND HEAT SHRINK | |

| DESCRIPTION | A wrap-around heat shrink made from MIL-SPEC tubing that repairs electrical systems and assembled components and is resistant to abrasion and chemicals. | A wrap-around, military-grade heat shrink paired with a high-temperature water blocking, hot-melt adhesive that protects against harsh environmental conditions. | |

| Closure | Tape (Specialty Surface) | Tape (Specialty Surface) | |

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Installation Type | Wrap-Around | Wrap-Around | |

| Purpose | Wire Repair | Water Blocking | |

| Min Temperature | Extreme | Extreme | |

| Minimum Operating Temperature | -67°F | -67°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 275°F | |

| Flexibility | |||

| View | View |

Guides

Shrink-N-Repair® (M) Wrap-Around Heat Shrink

A wrap-around, abrasion-resistant, fluid-resistant heat shrink that repairs wires or cables with diameters up to 0.5”.

Drawing Number(s):

Selected Part Number: RP-ZT16-04-012-B-X12.0

Features

Benefits

Shrink-N-Repair® (M) Wrap-Around Heat Shrink

Shrink-N-Repair® (M) Wrap-Around Heat Shrink

MATERIAL SPECIFICATIONS