Overview

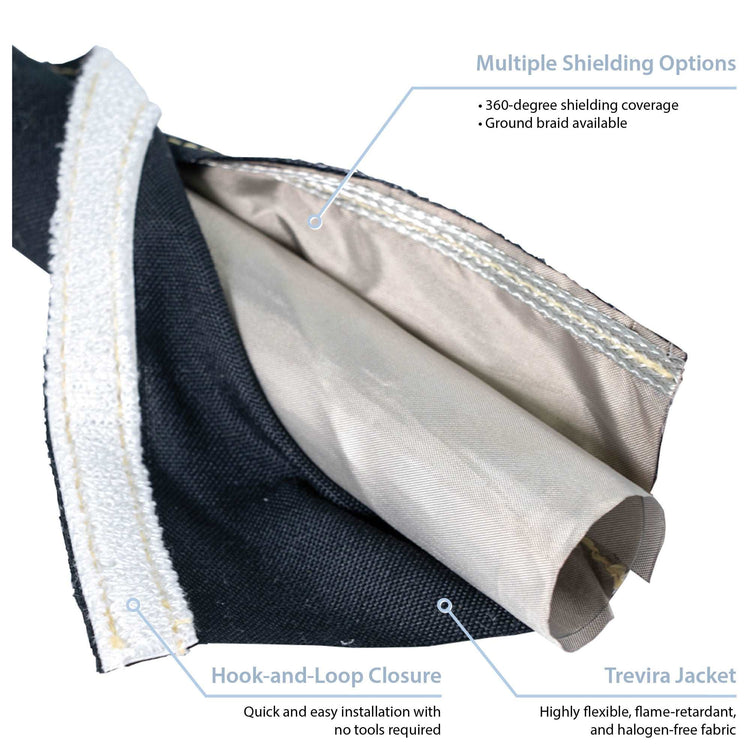

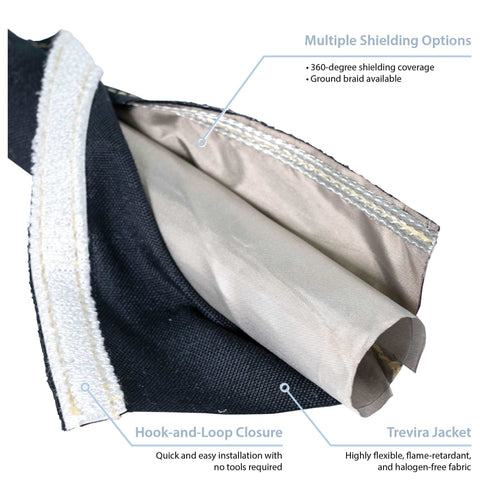

- Z-3250 fabric offers better EMI shielding

- cadmium-free Trevira jacketing

- Velcro-style closure requires no tools for installation

Hook-N-Shield™ (Trevira) consists of a lightweight (.015"), fire-retardant, woven-fabric jacketing that, if used with the right materials, could create a complete zero-halogen and cadmium-free product. Contact us today if you require a complete zero-halogen and/or cadmium-free Hook-It™ solution. The hook-and-loop (also known as Velcro®) closure is sewn using the double-stich technique that allows installation in many rugged applications.

Because of its versatility, the product offers a multitude of options including EMI shielding, Kevlar thread, or even high-temperature Aramid hook-and-loop (also known as Velcro®). When choosing this version of Hook-N-Shield™ (Trevira), the product also includes a ground wire sewn directly into it.

This product requires no additional tooling and can easily be closed and re-opened thanks to the hook-and-loop (also known as Velcro®) closure. Hook-N-Shield™ (Trevira) can be used indoors or outdoors.

About Treveria: Trevira jacketing material is self-extinguishing per FMVSS 302 and DIN 75200. It meets ASTM E 662 for smoke generation and Bombardier SMP 800-C for toxic gas generation. The jacketing material is also UV and Ozone stabilized. The patented Trevira material offers excellent wear resistance, 50,000 cycles per DIN 53863F T4.

- cadmium-free materials

- Self-extinguishing, UV and ozone stabilized jacketing

- Operational temperature range of -40°F to 248°F (-40°C to 120°C)

- Jacketing is lightweight and flexible, yet durable

- Hook-and-loop closure for easy accessibility and installation

- Shielding fabric protects from EMI, RFI and EMF

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shielding:

- Shielding Material:

Trevira

- REACH:

- Chemical Resistance:

- Flammability:

- Thickness:

- RoHS:

- Shelf Life:

- Temperature (Continuous):

- Temperature (Short Term):

Hook-and-Loop (Aramid)

Z-3250

Kevlar Thread

15 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Hook-N-Shield® (Trevira) EMI Shielded Cable Bundling

A lightweight, Trevira jacket paired with Z-3250 shielding fabric and a Velcro-style hook-and-loop closure.

Drawing Number(s): ZT13-13-002

Selected Part Number: ZT13-13-002-0.5-B-N

Features

Benefits

Hook-N-Shield® (Trevira) EMI Shielded Cable Bundling

SHIELDING EFFECTIVENESS - Z-3250

Hook-N-Shield® (Trevira) EMI Shielded Cable Bundling

MATERIAL SPECIFICATIONS