Overview

- Abrasion-resistant thermoplastic polyurethane jacketing

- Velcro-style closure requires no tools for installation

- Durable shielding mesh withstands rugged conditions

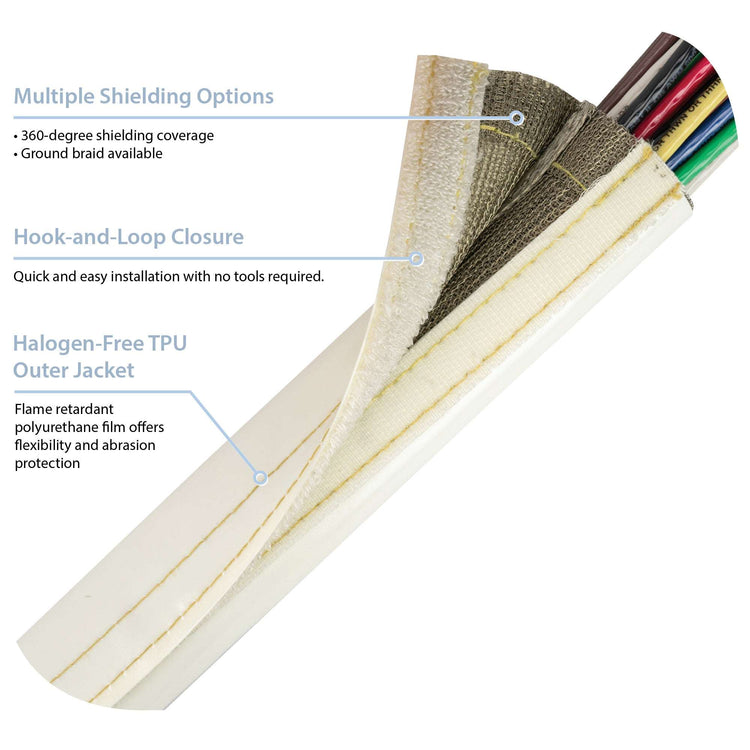

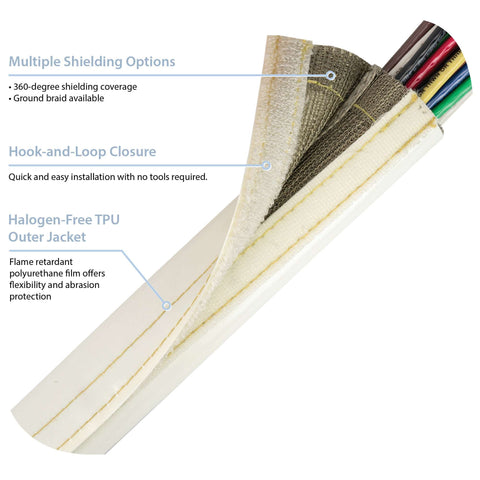

Hook-N-Shield® (TPU) is a wrap-around EMI shielding solution equipped with a Velcro® closure. The jacketing is a thermoplastic polyurethane (TPU) material that is 0.02” thick and UL-rated for flammability with meeting UL 94, V-0. The TPU jacketing is halogen free, abrasion resistant, microorganism resistant and ozone resistant (Stage 0, “Crack Free”). This jacketing’s properties meet requirements typically demanded in medical and clean room applications*.

The SHX-4 (SnCuFe) is a shielding mesh made from 4-ply tin-plated, copper clad steel wire. The mesh provides good shielding from EMI, RFI, and EMF, and is durable to last through rugged conditions. A 15 AWG braided wire is sewn to the shielding mesh for grounding capabilities. If you are looking for a shielding material that provides better protection from EMI, Hook-N-Shield® (TPU) can be equipped with either the Z-3250-CN or Z-7200-C shielding fabric upon request. The Z-3250 shielding fabric is made of a taffeta material plated with copper then nickel for excellent corrosion resistance. The Z-7200 fabric has a unique property of being non-magnetic and halogen-free, which is ideal for applications that have sensitive magnetic instrumentation and require halogen-free material.

The Aramid Velcro® closure requires no tools for installing Hook-N-Shield® (TPU). The hooks and loops easily engage for a secure closure, but can be peeled apart just as quickly to access components inside. The Velcro® is sewn to the TPU jacketing with an Aramid thread to ensure a strong seal of materials and to maintain the halogen-free product offering.

Hook-N-Shield® (TPU) is offered for diameters ranging from 0.5” to 6”, with custom shapes and sizes available upon request. The operational temperature range is -40°F to 257°F (-40°C to 125°C).

*Hook-N-Shield® (TPU) is not manufactured using a clean room in sterile conditions, but with the right procedures, it could be used in the medical field, including in hospitals, operating rooms, trauma centers, and emergency rooms.

- Resistant to microorganisms and ozone damage

- UL-rated for flammability with meeting UL 94, V-0

- Operational temperature range of -40°F to 257°F (-40°C to 125°C)

- TPU jacketing is ideal for medical and clean room applications

- Wrap-around solution allows for installation without disconnection of wires or cables

- Velcro-style closure provides the ability to access components as needed

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

TPU-20

- Durability:

- REACH:

- Elongation:

- Flammability:

- Color:

- Thickness:

- Thickness Variance:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

- Ozone Resistance:

Hook-and-Loop (Aramid)

SHX-4 (SnCuFe)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Hook-N-Shield® (TPU) EMI Shielded Halogen-Free Bundling

A wrap-around component protection solution with TPU jacketing, EMI shielding mesh and a Velcro-style hook-and-loop closure.

Drawing Number(s): ZT17-13-011

Selected Part Number: ZT17-13-011-0.5-W-W

Features

Benefits

Hook-N-Shield® (TPU) EMI Shielded Halogen-Free Bundling

SHIELDING EFFECTIVENESS - SHX-4 (SnCuFe)

Hook-N-Shield® (TPU) EMI Shielded Halogen-Free Bundling

MATERIAL SPECIFICATIONS