Overview

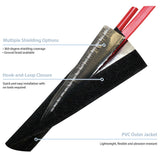

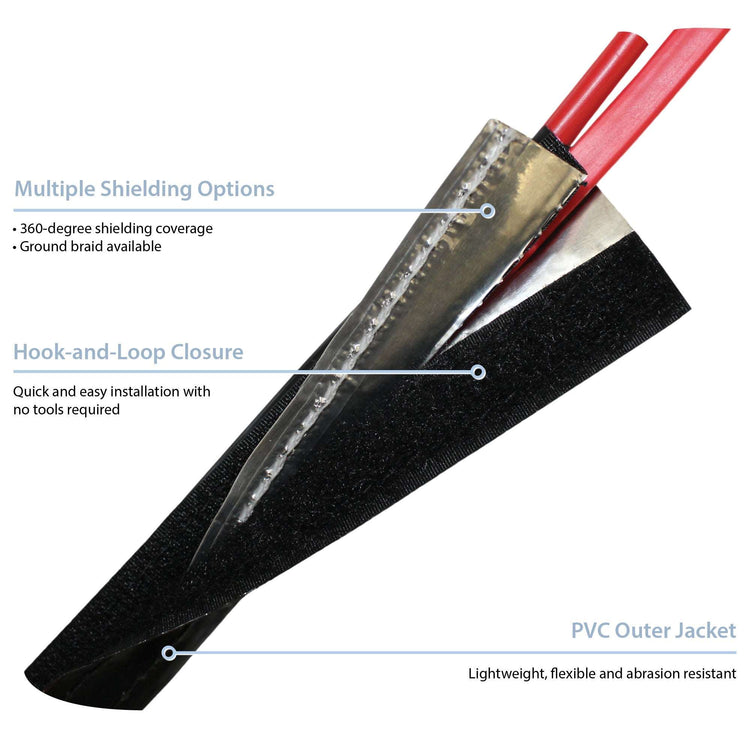

- Hook-and-loop closure requires no tools

- SH1 laminate provides superior EMI shielding

- 63-10 jacketing offers abrasion protection

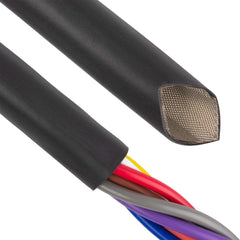

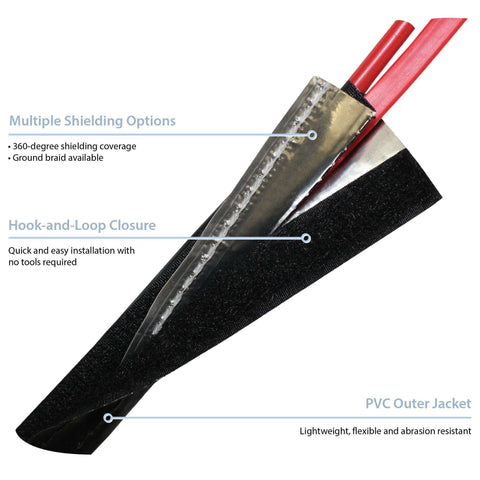

Hook-N-Shield® (63) is a wrap-around solution for shielding components from EMI, RFI and EMF. The outer jacket, made of 63-10 material, is lightweight and only 0.010” thick, military grade and RoHS compliant. This material is also resistant to abrasion, corrosion, fluid and fungus—perfect for applications needing protection in harsh environments. The inner jacket, lined with SH1 shielding laminate, offers superior EMI shielding.

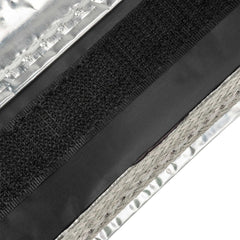

The nylon Velcro-style hook-and-loop closure enables quick installation with no tools required; and allows for easy access to components as needed. Hook-N-Shield® (63) can be equipped with a 3/16” flat tin/copper drain wire for applications needing a full length, sewn-in ground wire.

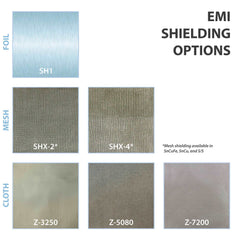

Hook-N-Shield® (63) is the ideal EMI shielding solution for applications that will not experience flexing or movement. For flexing applications, Hook-N-Shield® with SHX provides good EMI shielding while also allowing for flexing without compromising shielding performance. Custom Hook-N-Shield® solutions made with other materials are available upon request.

Hook-N-Shield® (63) diameters range from 0.375” to 4”, with custom sizes available. The operational temperature range is -4°F to 200°F (-20°C to 93°C).

- Velcro-style closure for re-entry to components as needed

- 63-10 protective jacketing material for rugged environments

- Operational temperature range of -4°F to 200°F (-20°C to 93°C)

- Resistant to abrasion, copper corrosion, fluid and fungus

- SH1 laminate provides excellent EMI shielding

- Optional drain wire for grounded applications

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Hook and Loop:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shielding:

- Shielding Material:

63-10

- Mil-Spec:

- REACH:

- Copper Corrosion:

- Dielectric Volts/Mil:

- Dielectric Constant:

- Elongation:

- Volume Resistivity:

- Flame Retardant:

- Fungicide:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Dissipation Factor:

- Tensile Strength:

Hook-and-Loop (Nylon)

SH1 (Laminate)

Nylon Thread

15 AWG Braided Ground Straps

5/8" / 1"

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -67°F | -40°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | |

| Flexibility | |||

| View | View |

Hook-N-Shield® (63) Cable Bundling with EMI Shielding

A wrap-around, EMI shielding solution with a Velcro-style hook-and-loop closure paired with a lightweight 63-10 jacket and high-performing aluminum shielding laminate.

Drawing Number(s): ZT98-13-009

Selected Part Number: ZT98-13-009-0.375-B-B

Features

Benefits

Hook-N-Shield® (63) Cable Bundling with EMI Shielding

SHIELDING EFFECTIVENESS - SH1 (Laminate)

Hook-N-Shield® (63) Cable Bundling with EMI Shielding

MATERIAL SPECIFICATIONS