Overview

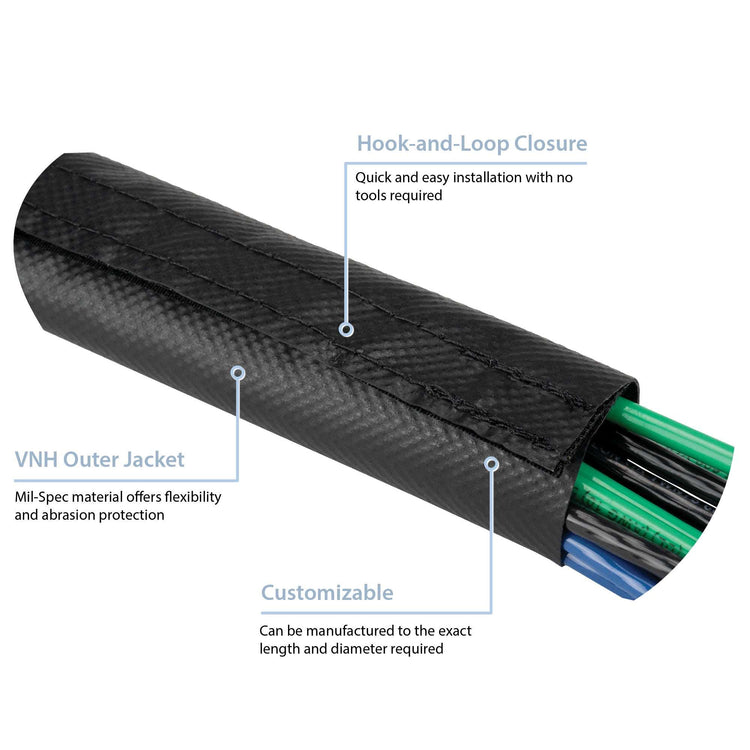

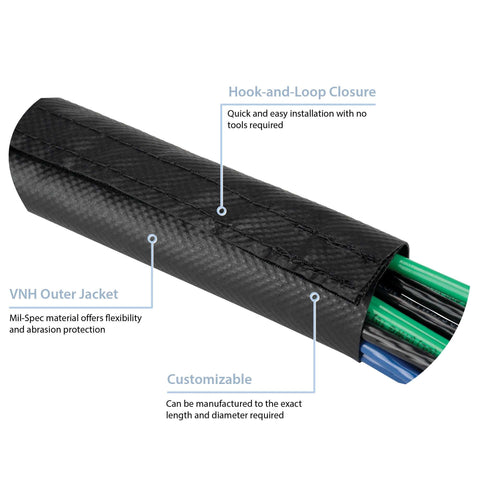

- VNH-23 military-grade jacketing

- Velcro-style closure for easy install

- National Stock Number (NSN) for 1" diameter

Hook-It® (VNH) is a cable management system that pairs VNH-23 military-grade jacketing with a Velcro-style hook-and-loop closure system. The PVC-coated VNH jacketing is 0.023” thick, as well as flame retardant and waterproof. This jacketing provides strong bundling and protection and is ideal for wires or cables exposed to harsh environmental conditions.

The Velcro-style closure is one of the easiest closure systems, as it requires no tools for installation. The nylon hooks and loops engage together to provide a secure closure, but can be easily pulled apart for quick access to wires or cables inside. The hook-and-loop material conforms to GSA specification A-A-55126, Type II, Class 1. The closure is sewn to the VNH jacketing with a black nylon thread.

Hook-It® (VNH) is offered in diameters ranging from 0.5” to 8”, with custom shapes and sizes available upon request. The 1” diameter has an assigned NSN for easy procurement. The operational temperature range of Hook-It® (VNH) is -65°F to 171°F (-54°C to 77°C).

Hook-It® (VNH) is available with National Stock Numbers (NSN). This designation ensures that Hook-It® (VNH) meets the stringent standards required by military and government agencies, facilitating easy procurement and inventory management. The availability of Hook-It® (VNH) with NSNs underscores Zippertubing's commitment to quality and reliability in providing essential components for critical operations.

- VNH-23 jacketing for rugged conditions

- Hook-and-loop closure allows for quick and easy access to wires or cables

- Operational temperature range of -65°F to 171°F (-54°C to 77°C)

- Military-grade jacketing is flame retardant and waterproof

- Wrap-around solution allows for installation without disassembly

- Lightweight, yet provides durable protection

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Cable Diameter:

- Closure:

- Material:

- Hook and Loop:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

VNH-23

- Mil-Spec:

- Durability:

- REACH:

- Flame Retardant:

- Thickness:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

Hook-and-Loop (Nylon)

Nylon Thread

5/8" / 1"

Similar products

|

|

|

|

| NAME | ZIP-ON® (63) MILITARY-GRADE CABLE BUNDLING | ZIP-ON® (PFR) POLYURETHANE CABLE BUNDLING | Z-COIL SELF-CLOSING CABLE JACKETING |

| DESCRIPTION | A wrap-around cable bundling and protection solution that has a PVC, military-grade jacket that is abrasion and fluid resistant, with a pressure track. | A wrap-around cable protection solution that is flexible, resistant to abrasion and fluids, and has a pressure track closure. | A self-closing wire bundling and protection sleeve made from a durable, flame-retardant, woven PET material |

| Closure | Z-Track (PVC), R-Track (PVC), D-Track (PVC), EZ-Track (PVC) | Z-Track (PFR) | Self-Closing |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Wrap-Around | Wrap-Around | Wrap-Around |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Low | Moderate | Extreme |

| Minimum Operating Temperature | -4°F | -67°F | -58°F |

| Max Temperature | Moderate | Low | Moderate |

| Maximum Operating Temperature | 221°F | 225°F | 302°F |

| Flexibility | Better | Best | Best |

| View | View | View |

Hook-It® (VNH) Military-Grade Cable Bundling

A wrap-around, military-grade, flame-retardant cable management solution utilizing a Velcro-style hook-and-loop closure system for quick re-entry.

Drawing Number(s): ZT97-13-006

Selected Part Number: ZT97-13-006-1.0-B-B

Features

Benefits

Hook-It® (VNH) Military-Grade Cable Bundling

Hook-It® (VNH) Military-Grade Cable Bundling

MATERIAL SPECIFICATIONS