Overview

- Offers good EMI shielding (30 MHz to 1 GHz)

- Flexible and lightweight—ideal for the aerospace industry

- Flame retardant and meets UL1441, VW-1

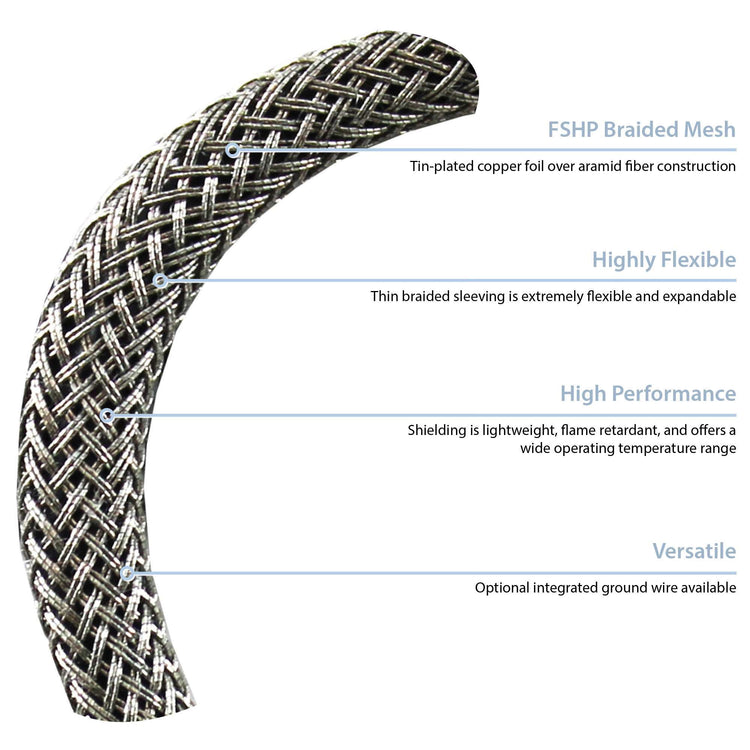

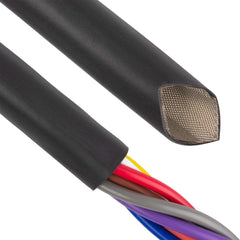

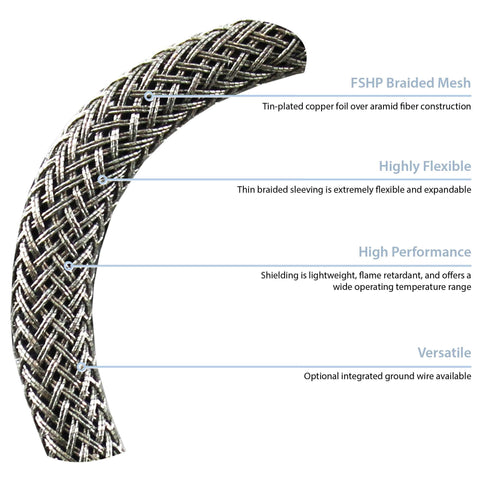

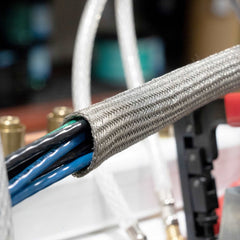

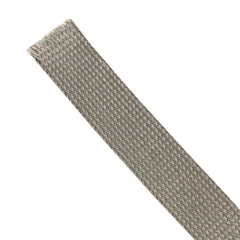

Flex-Shield™ (HP) is a high-flexing, EMI-shielding sleeve. It is made of two-ply twisted meta-aramid (Nomex) threads that have tin-plated copper foil strips helically wound around each thread, then braided together to create the expandable tubular sleeve. Flex-Shield™ (HP) is extremely flexible yet thin, with a material thickness of only 0.025”. Because it can expand or shrink considerably, Flex-Shield™ (HP) can work on applications that fluctuate in sizing. The expandable sleeve has a wide temperature range of -40°F to 302°F (-40°C to 150°C) and is RoHS compliant, fluid resistant and UL-rated for flammability, meeting UL1441, VW-1 specifications. Flex-Shield™ (HP) can be equipped with a woven-in braided wire for grounding needs.

Flex-Shield™ (HP) is currently being utilized for a variety of aerospace applications. Due to its lightweight and non-metallic core material, Flex-Shield™ (HP) is the “Aerospace Ace,” providing EMI shielding and a durable barrier between components and environmental conditions. Flex-Shield™ (HP) is available in sizes ranging from 0.125” to 1.5” in diameter, with custom sizing available upon request.

- Pull-through solution for complete coverage

- Flame-retardant and fluid-resistant materials

- High-temperature range of up to 302°F (150°C)

- Offers EMI, RFI and EMF shielding of components

- No tools required for installation

- RoHS compliant and UL-rated

Product Data

| Diameter | Grams/Foot Without Ground | Grams/Foot With Ground |

|---|---|---|

| 0.125" (1/8) | 2.29 | 3.34 |

| 0.375" (3/8) | 5.22 | 6.27 |

| 0.5" (1/2) | 7.55 | 8.60 |

| 0.75" (3/4) | 10.58 | 11.63 |

| 1.0" | 13.36 | 14.41 |

| 1.25" (1 1/4) | 15.08 | 16.13 |

| 1.5" (1 1/2) | 20.29 | 21.34 |

Please Note: Flex-Shield® with ground adds an additional weight of 1.05g per 12". See "w/ground grams".

Specifications

Overall Performance

- Cable Diameter:

- Expandability:

- Flame Retardant:

- Thickness:

- Material Type:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

FSHP

None

21 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | SHRINK-N-SHIELD® (3:1) EMI SHIELDED HEAT SHRINK TUBING | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A heat-shrink tubing that provides exceptional shielding from EMI, RFI and EMF. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | Best | |

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Small Diameters | |

| Min Temperature | Extreme | Extreme | |

| Minimum Operating Temperature | -67°F | -67°F | |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 275°F | |

| Flexibility | |||

| View | View |

Flex-Shield (HP) Braided EMI Shielding Sleeve

A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry.

Drawing Number(s): ZT01-19-001, ZT15-19-001

Selected Part Number: ZT01-19-001-0.75-X3936.0

Features

Benefits

Flex-Shield (HP) Braided EMI Shielding Sleeve

SHIELDING EFFECTIVENESS - FSHP

PRODUCT DATA

| Diameter | Grams/Foot Without Ground | Grams/Foot With Ground |

|---|---|---|

| 0.125" (1/8) | 2.29 | 3.34 |

| 0.375" (3/8) | 5.22 | 6.27 |

| 0.5" (1/2) | 7.55 | 8.60 |

| 0.75" (3/4) | 10.58 | 11.63 |

| 1.0" | 13.36 | 14.41 |

| 1.25" (1 1/4) | 15.08 | 16.13 |

| 1.5" (1 1/2) | 20.29 | 21.34 |

Please Note: Flex-Shield® with ground adds an additional weight of 1.05g per 12". See "w/ground grams".

Flex-Shield (HP) Braided EMI Shielding Sleeve

MATERIAL SPECIFICATIONS