Overview

- Adhesive sticks to EMI shielding for easier installation and will outlast harsh conditions to ensure a long-lasting solution

- Shields from EMI, RFI, and EMF

- Operational temperature range of -40°F to 235°F (-40°C to 113°C)

- Heavy wall tubing protects from the toughest of conditions and environments

- Z-3250-CN shielding fabric has a nickel coating for excellent corrosion resistance

- Installation only requires a standard heat gun

- Heavy wall heat-shrink tubing is UL-rated meeting UL 486D

- EMI shielding fabric provides better protection from electromagnetic interference

- Shrink ratio of 3:1 allows for versatility in application uses

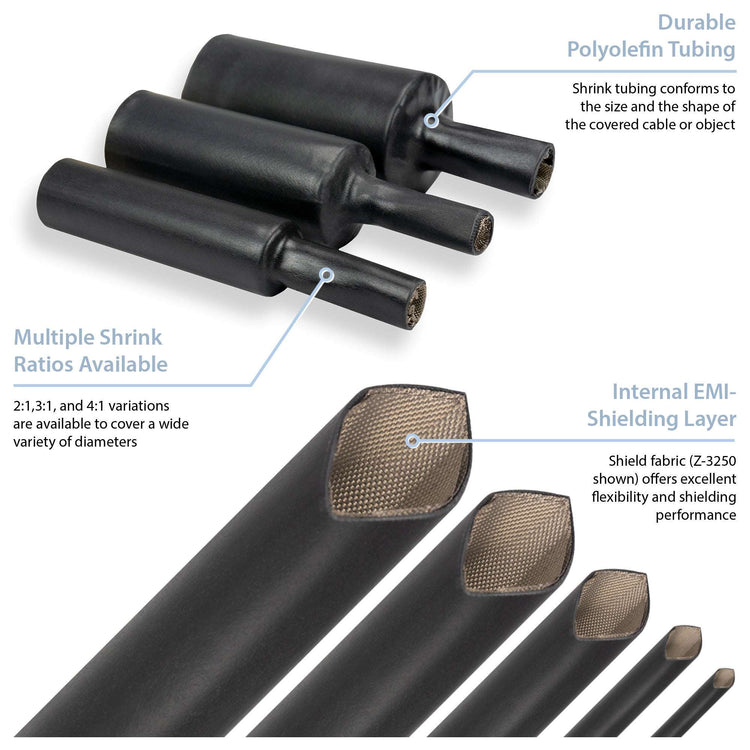

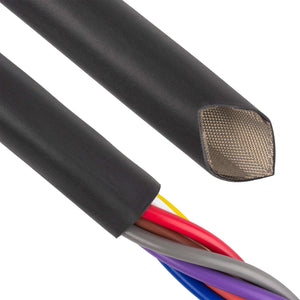

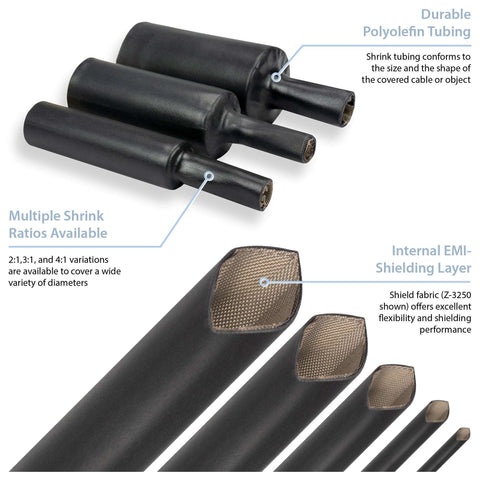

Shrink-N-Shield® (HW) combines two proven technologies into a single, easy to install product for adding EMI shield protection to wire and cable bundles with diameters of 1/2" and less. Makes adding an EMI shield or secondary EMI shielding to wire and cable a snap. This product is comprised of SAE-AMS-DTL-23053/15 (w/o the adhesive layer) heat shrink tubing and Zippertubing's Z-3250 conductive cloth which has outstanding shielding properties. It is ideal for applications where thick, heavy wall insulation is needed for superior mechanical protection. This product has an operational temperature range of -55°C to 110°C. This product is supplied in four foot long sticks.

Specifications

Overall Performance

- Diameter - Before Shrink:

- Material:

- Heat Shrink Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shelf-Life:

- Shield Bonding:

- Shielding:

- Shielding Material:

- Shrink Ratio:

Heavy Wall Polyolefin

- Elongation:

- Flammability:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Shelf Life:

- Shrink Ratio:

- Tensile Strength:

Z-3250

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -40°F | -40°F | °F |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | °F |

| Flexibility | |||

| View | View |

Guides

Shrink-N-Shield® (HW) EMI Shielded Heat Shrink Tubing

A durable, heavy wall heat-shrink tubing paired with the Z-3250-CN shielding fabric to protect from EMI.

Drawing Number(s): ZT04-18-002

Selected Part Number: ZT04-18-002-01-B-X48.0

Features

Benefits

Shrink-N-Shield® (HW) EMI Shielded Heat Shrink Tubing

SHIELDING EFFECTIVENESS - Z-3250

Shrink-N-Shield® (HW) EMI Shielded Heat Shrink Tubing

MATERIAL SPECIFICATIONS