Overview

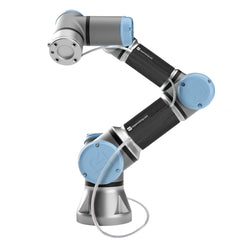

- Engineered for UR3, UR5, and UR10 Universal Robots

- Velcro-style closure for easy installation

- Customizable number of channels and branding

Channel-Wrap® is a wraparound sleeve that, depending on your environment, can be manufactured from a multitude of materials and offers a variety of different types of closure options. The advantage of utilizing this sleeve is having the ability to wrap the sleeve around a robotic arm, a post, a railing, or any other component, and then route cables, wires, or hoses through the channels built into the closure portion of the sleeve.

These particular Channel-Wrap® products are comprised of Zippertubing’s best-in-abrasion, non-PVC, PFR-18 jacketing material that is extremely flexible, resistant to most fluids, flame retardant and meets military specifications. This material also allows cables, wires, tubes or hoses to easily move within the jacketing. Channel-Wrap® (PFR) closes using a Velcro-style hook-and-loop closure.

Fun fact: Channel-Wrap® was originally designed for Zippertubing’s own production needs, as Zippertubing® currently utilizes a Universal Robot brand machine in its own production environment. After the initial set up of the robot to complete a job, we realized that we could manufacture a wrap-around robot cable sleeve that would not only securely hold an air hose line, but allow the air hose to move with each of the robots actions.

Whether you are looking for a simple collaborative robot cable bundling product, or something that may need to handle harsher environments, such as high temperatures, Zippertubing® can customize a solution to fit your specific application requirements.

- RoHS compliant, military-grade, and UL-rated jacketing

- Many different customization options for a one-of-a-kind cable bundling solution

- Operational temperature range of -67°F to 200°F (-55°C to 93°C)

- Covers and bundles components giving a clean appearance and flexible protection

- No tools required for installation

- PFR-18 is free of PVC for applications with such restrictions

Specifications

Overall Performance

- Robot Arm Type:

- Branding:

- Closure:

- Material:

- Kit Contains:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- Number of Channels:

- RoHS:

PFR-10

- Copper Corrosion:

- Dielectric Volts/Mil:

- Dielectric Strength:

- Elongation:

- Flammability:

- Durometer:

- Fungus Resistance:

- Color:

- Thickness:

- Thickness Variance:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Tensile Strength:

- Ozone Resistance:

- Specific Gravity:

Hook-and-Loop (Nylon)

Nylon Thread

Similar products

|

|

|

|

| NAME | Z FLEX® (PFR) POLYURETHANE PULL-THROUGH CABLE SLEEVE | Z FLEX® (63) PVC PULL-THROUGH CABLE SLEEVE | ZTT® (PVL) PULL-THROUGH WIRING SLEEVE |

| DESCRIPTION | A military-grade, flame-retardant, pull-through cable and wire protection solution that has a nylon cloth leader. | A pull-through bundling sleeve equipped with a nylon cloth leader, made of a 0.02” thick military-grade material that offers protection from abrasion & fluid. | A pull-through cable sleeving solution with a fire-retardant jacket that is available in multiple colors—equipped with a nylon cloth leader for easy installation. |

| Closure | |||

| RoHS | RoHS-6 | RoHS-6 | RoHS-10 |

| Abrasion Resistance | Best | Best | Better |

| Installation Type | Pull Through | Pull Through | Pull-Through |

| Purpose | Sleeve | Sleeve | Sleeve |

| Min Temperature | Extreme | Low | Moderate |

| Minimum Operating Temperature | -67°F | -4°F | -40°F |

| Max Temperature | Moderate | Moderate | Low |

| Maximum Operating Temperature | 224°F | 221°F | 179°F |

| Flexibility | Best | Better | Better |

| View | View | View |

Channel-Wrap® (PFR) Robotic Cable Sleeving

A flexible, wrap-around robotic cable management sleeve with a Velcro-style hook-and-loop closure for bundling and protecting crucial wires and cables.

Drawing Number(s): ZT19-KT-005

Selected Part Number: ZT19-KT-005-03-**

Features

Benefits

Channel-Wrap® (PFR) Robotic Cable Sleeving

Channel-Wrap® (PFR) Robotic Cable Sleeving

MATERIAL SPECIFICATIONS