Overview

- Mil-Spec Jacketing Product

- Waterproof & Hydrocarbon Fluid Resistance

- Flame Retardant, FAR 25.853

- Extreme Low Temperature Performance

- Excellent Abrasion Resistance

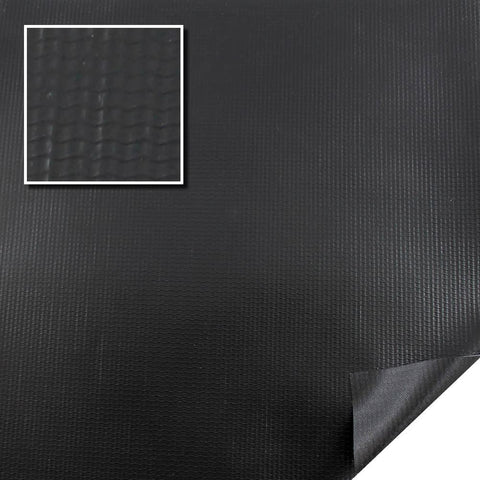

VNH-23 is a medium weight (.023") low temperature PVC coated Nylon fabric that conforms to Mil-C-20696 / Mil-PRF-20696, Type II, Class 2. The material is extremely flexible, even at low temperatures, has high break strength and is abrasion resistant. VNH-23 is ideal for outdoor applications where wire or cables are exposed to weathering, abuse, abrasion, rock impact or where tear strength is important. The material is flame retardant and will pass FAR 25.853, paragraph B requirements. This material comes standard in black or yellow but any FED-STD-595 color is available on a custom order basis. All Zippertubing closure styles are available. VNH-23 is an extremely versatile material and has been used in both commercial and military applications including aircraft anti-chaff protection, marine dockside cable protection and Antarctic Research programs. The material has an operating temperature range of -65° to 171 ° F (-54 ° to 77 ° C ).

Specifications

Similar Materials

|

|

|

|

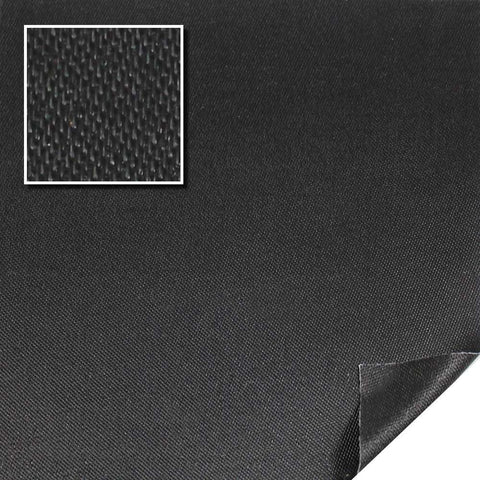

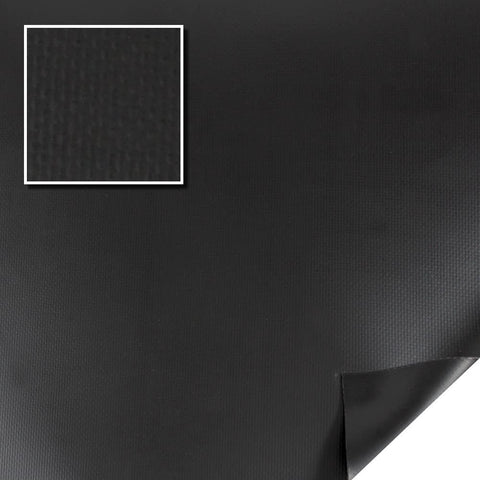

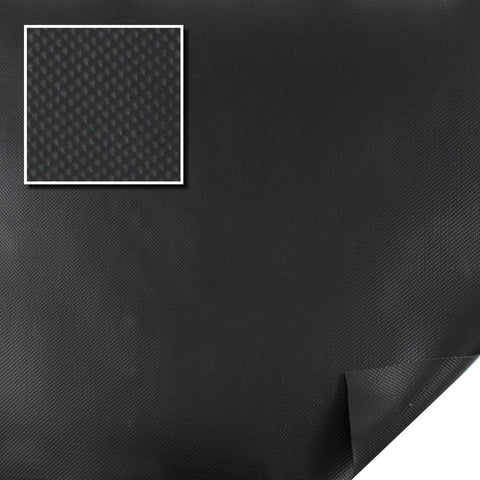

| NAME | DVH-20 - PVC COATED POLYESTER - 20 MIL | SRFG-32 - SILICONE COATED FIBERGLASS FABRIC - 32 MIL | DVH-40 - PVC COATED POLYESTER - 40 MIL |

| DESCRIPTION | General Purpose PVC Coated Polyester Jacket, 20 Mil | Heavy Duty Silicone Coated Fiberglass Jacket, 32 Mil | Heavy Duty PVC Coated Nylon/Polyester Jacket, 40 Mil |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Better | Best | |

| Min Temperature | Moderate | Extreme | Moderate |

| Minimum Operating Temperature | -30°F | -65°F | -40°F |

| Max Temperature | Low | Extreme | Low |

| Maximum Operating Temperature | 185°F | 449°F | 180°F |

| Flexibility | Good | Good | |

| View | View | View |

VNH-23 - PVC Coated Nylon Fabric - 23 Mil

Mil-Spec PVC Coated Nylon Jacket, 23 Mil

Material Sprcification: 1102

- Mil-Spec Jacketing Product

- Waterproof & Hydrocarbon Fluid Resistance

- Flame Retardant, FAR 25.853

- Extreme Low Temperature Performance

- Excellent Abrasion Resistance

SPECIFICATIONS

DESCRIPTION

VNH-23 is a medium weight (.023") low temperature PVC coated Nylon fabric that conforms to Mil-C-20696 / Mil-PRF-20696, Type II, Class 2. The material is extremely flexible, even at low temperatures, has high break strength and is abrasion resistant. VNH-23 is ideal for outdoor applications where wire or cables are exposed to weathering, abuse, abrasion, rock impact or where tear strength is important. The material is flame retardant and will pass FAR 25.853, paragraph B requirements. This material comes standard in black or yellow but any FED-STD-595 color is available on a custom order basis. All Zippertubing closure styles are available. VNH-23 is an extremely versatile material and has been used in both commercial and military applications including aircraft anti-chaff protection, marine dockside cable protection and Antarctic Research programs. The material has an operating temperature range of -65° to 171 ° F (-54 ° to 77 ° C ).