Overview

- EMI Shielding (500 KHz to 1 GHz)

- Extremely Flexible & Durable

- Extremely Corrosion Resistant

- Non Flammable & Heat Resistant

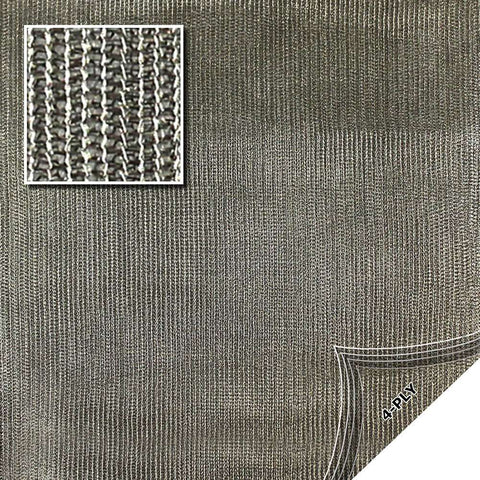

SHX-4 (S/S) is a flexible 4 layer knitted wire mesh EMI shielding material that is made of 304 Stainless Steel wire. The knitted mesh design creates a highly flexible shield that unlike many tubular braids will not change attenuation performance when articulated. The knitted wire mesh maintains constant window spacing during cable assembly movement and as a result yields excellent EMI shielding performance from 500 KHz through 1 GHz. The material is conductive, rugged and is ideal for severe environment and highly corrosive applications. The mesh can be added to most Zippertubing® jacket materials to create an easy to install Zip-on EMI shielded assembly. SHX-4 (S/S) shields come with a standard 15 AWG drain wire attached to simplify grounding. This material has been used to provide rodent protection, EMI Shielding in seawater and extremely high temperature applications.

Specifications

Shielding Effectiveness

SHX-4 (S/S) 4-Ply Stainless Steel Wire Mesh

Stainless Steel Wire EMI Shielding Mesh, 4-Ply

Material Sprcification: 3104

- EMI Shielding (500 KHz to 1 GHz)

- Extremely Flexible & Durable

- Extremely Corrosion Resistant

- Non Flammable & Heat Resistant

SPECIFICATIONS

DESCRIPTION

SHX-4 (S/S) is a flexible 4 layer knitted wire mesh EMI shielding material that is made of 304 Stainless Steel wire. The knitted mesh design creates a highly flexible shield that unlike many tubular braids will not change attenuation performance when articulated. The knitted wire mesh maintains constant window spacing during cable assembly movement and as a result yields excellent EMI shielding performance from 500 KHz through 1 GHz. The material is conductive, rugged and is ideal for severe environment and highly corrosive applications. The mesh can be added to most Zippertubing® jacket materials to create an easy to install Zip-on EMI shielded assembly. SHX-4 (S/S) shields come with a standard 15 AWG drain wire attached to simplify grounding. This material has been used to provide rodent protection, EMI Shielding in seawater and extremely high temperature applications.

SHX-4 (S/S) 4-Ply Stainless Steel Wire Mesh

SHIELDING EFFECTIVENESS