Overview

- Shields EMI and RFI

- Anti-corrosive

- Lightweight, flexible and RoHS compliant

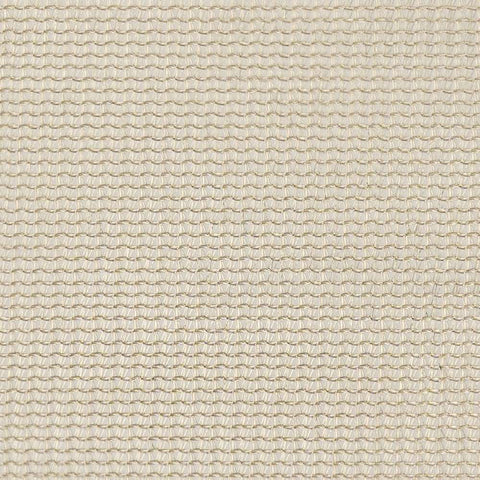

Sheer-Shield® is made from a thin polyester mesh, plated with copper then nickel, for protection against EMI and RFI. This RoHS-compliant material is lightweight, flexible and anti-corrosive; and does not flake or rub off during normal handling. Sheer-Shield® is nickel in color and has an operational temperature range from -40°F to 250°F (-40°C to 121°C).

Specifications

Sheer-Shield® Nickel Over Copper Polyester Mesh

Sheer-Shield® is a lightweight, flexible, RoHS-complaint, nickel over copper polyester mesh that provides protection from EMI, RFI and corrosion.

Material Sprcification: 3214

- Shields EMI and RFI

- Anti-corrosive

- Lightweight, flexible and RoHS compliant

SPECIFICATIONS

DESCRIPTION

Sheer-Shield® is made from a thin polyester mesh, plated with copper then nickel, for protection against EMI and RFI. This RoHS-compliant material is lightweight, flexible and anti-corrosive; and does not flake or rub off during normal handling. Sheer-Shield® is nickel in color and has an operational temperature range from -40°F to 250°F (-40°C to 121°C).