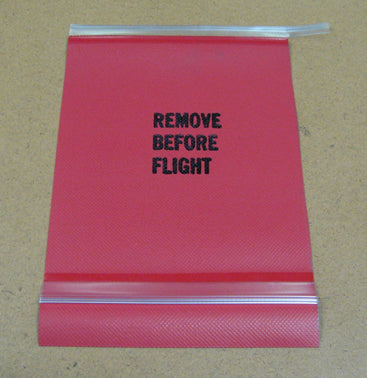

Missile Canard Retention Sleeve

PROBLEM:

A military customer requested an inexpensive solution to retain missile canards in a retracted condition while missiles were in storage crates and attached to Helicopter launch pylons prior to flight. The part needed to be disposable, yet able to withstand all military operation environments.

REQUIREMENTS:

A suitable material had to remain highly flexible over long periods of storage and strong enough to hold the missile canards in a retracted state indefinitely both in storage and when installed on a launch pylon. While on a pylon the material had to provide a quick tear-off feature and be a disposable component. The required environmental conditions were defined as an operational temperature range of -60 to +75ºC, highly flexible at both temperature extremes, weather-resistant, UV-and fungus-resistant, fire-retardant and available in red color. The material also needed to have a permanent printed instruction logo on the outside stating “Remove Before Flight”. The marking method was requested to be hot stamped.

SOLUTION:

The Zippertubing Company utilized its tough and flexible PVC, polymer-impregnated Nylon fabric material known as VNH-23. The VNH-23 material conforms to Mil-C-20696, Type II, Class 2 and met all specified performance requirements. VNH-23 is also a heat-sealable material which is available in red Fed-Std-595 colors. Zippertubing heat welded its standard clear color, thumb-pressure extruded interlock track known as S-Track to each side of the material. The top side of the track extended beyond the material edge so as to create a “pull tab” for easy removal prior to flight. The sheer size of the logo font required, >1.0 inches, made the hot-stamping marking method impractical. Zippertubing created a series of marking test samples for customer evaluation since pad printing was not an approved method in the customer’s marking document. Zippertubing had invested in modern pad printing technology several years earlier and knew the performance of pad printing inks on flexible PVC polymers. Customer testing showed that the pad printing method met the permanence requirements and they accepted this methodology. A large black-block font was successfully pad printed to the outside of each part.

CONCLUSION:

The solution above was tested and incorporated by the customer, and field performance has yielded exceptional results to date (10+ years of service). The Zippertubing Company’s marking technology successfully changed the customers preconceived notion of marking permanence on flexible polymer materials. If you have what seems to be an impossible design problem and difficult performance requirements, contact Zippertubing for innovative and novel solutions!