Overview

- RoHS compliant and non-flammable two-ply or four-ply knitted mesh

- Zipper closure for a no tools required installation

- Operational temperature range of -40°F to 248°F (-40°C to 120°C)

- Knitted shielding mesh protects components from abrasion

- Zipper closure saves installation time

- Grounding drain wire for applications with such requirements

- Interior overlap to ensure 360° EMI shielding

- Flexible and non-flammable shielding mesh

- Zipper closure allows for toolless installation

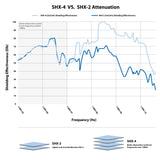

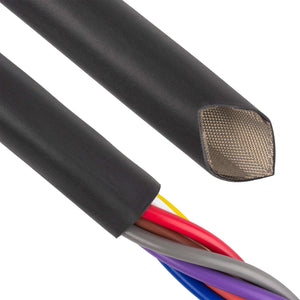

Zipper-Mesh™ is an efficient and durable EMI, RFI and EMF shielding solution. Featuring a zipper closure, Zipper-Mesh™ is easy to install and requires no tools. Choose either SHX-2 (two-ply) or SHX-4 (four-ply) knitted shielding mesh to protect components from abrasion. SHX-4 is suited for higher frequencies of 13 megahertz or more.

The knitted mesh is made from a tin-plated copper clad and steel wire. The mesh is extremely flexible, RoHS compliant, non-flammable and has no exterior jacketing, allowing for easy ground termination. Additionally, the mesh has an interior overlap to ensure 360-degree EMI shielding.

The plastic zipper closure glides effortlessly for quick application and re-entry. The braided grounding strap also enables grounding for applications with such requirements.

We offer Zipper-Mesh™ for diameters ranging from 0.5” to 15”, with custom diameters available upon request. Zipper-Mesh™ has an operational temperature range of -40°F to 248°F (-40°C to 120°C).

Specifications

Overall Performance

- Diameter:

- Closure:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf-Life:

- Shielding:

- Shielding Material:

- Zipper Color:

Zipper (Nylon)

SHX-2 (SnCuFe)

SHX-4 (SnCuFe)

Nylon Thread

15 AWG Braided Ground Straps

Similar products

|

|

||

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -40°F | -40°F | °F |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | °F |

| Flexibility | |||

| View | View |

Zipper-Mesh (No Jacket) EMI Shielded Cable Bundling

Zipper-Mesh™ is an EMI-shielding solution made from either a two-ply or four-ply knitted shielding mesh—equipped with a zipper closure for quick and easy application.

Drawing Number(s): ZT23-07-001, ZT01-07-006

Selected Part Number: ZT23-07-001-0.5-B

Features

Benefits

Zipper-Mesh (No Jacket) EMI Shielded Cable Bundling

SHIELDING EFFECTIVENESS - SHX-2 (SnCuFe), SHX-4 (SnCuFe)

Zipper-Mesh (No Jacket) EMI Shielded Cable Bundling

MATERIAL SPECIFICATIONS