Overview

- Engineered for diameters ranging from 0.375 to 4, with custom sizes available upon request

- Pressure track is heat sealed to jacketing for strong bond

- Can be equipped with a 15 AWG braided ground wire

- Superior EMI shielding with SH1 foil

- Wide range of jacketing options to fit any application or condition

- Can be engineered for round, flat, or custom cables

- Pressure Track Closure

- Extruded Films and Coated Fabric jackets available

- Foil EMI/RFI shielding material

- Easy to use installation pliers and slider tools

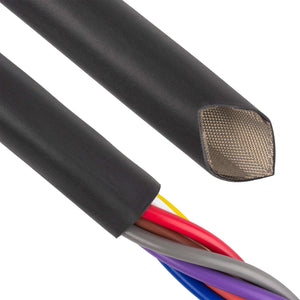

Zip-Shield® (SH1) is an EMI shielding solution constructed of a jacket with the SH1 EMI shielding foil and a pressure track. The jacketing is dependent on application requirements – whether you need a jacket that is military grade and flame retardant, or is free of PVC material and provides exceptional abrasion resistance, Zip-Shield® (SH1) is offered in a wide range of jacketing options. The SH1 shielding foil is perfect for shielding against higher frequency and for applications that will not experience any flexing or movement. If you require a solution that can install easily, the Zip-Shield® product line is also available with the knitted EMI shielding mesh, Zip-Shield® (SHX4), or an EMI shielding cloth, Zip-Shield® (3250) or Zip-Shield® (7200). The Zip-Shield® product line can also be equipped with a sewn-in 15 AWG drain wire for grounded applications.

Zip-Shield® (SH1) is typically paired with the R-Track or Z-Track. Both pressure track systems will be easy to seal and offer a long-lasting closure, and if the need to re-enter is required, you can access components easily. The Z-Track is a medium-duty pressure track closure that has an arrowhead and channel interlock system, and is the most versatile pressure track option. The Z-Track can be sealed with our ZTZ-SP plier tool. The R-Track is a light-duty pressure track closure and is similar to a zip-lock closure. The R-Track can be sealed manually with thumb or with a SLR slider tool.

Zippertubing® can also manufacture Zip-Shield® (SH1) with our other pressure track closures upon request.

63-10: Flexible and lightweight PVC film that is 0.01” thick, military grade, abrasion resistant and fluid resistant.

63-20: Flexible and medium weight PVC film that is 0.02” thick, military grade, abrasion resistant and fluid resistant.

PFR-18: Extremely flexible polyurethane film that has excellent abrasion and fluid resistance, as well as being military grade and flame retardant.

VNH-23: Extremely flexible and medium weight nylon fabric that has a PVC coating, is military grade, flame retardant, and provides durable protection for applications in rugged environmental conditions.

PTG-5: Lightweight PTFE-coated fiberglass fabric that is military-grade, chemical resistant and able to handle high-temperatures.

RPU-17: Flexible and medium weight, white polyurethane and polyester fabric jacketing that is tear resistant and flame retardant.

FREQUENTLY ASKED QUESTIONS

Specifications

Overall Performance

- Diameter:

- Closure:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shielding:

- Shielding Material:

PFR-18

- Mil-Spec:

- Copper Corrosion:

- Dielectric Constant:

- Dielectric Strength:

- Elongation:

- Flame Retardant:

- Fungus Resistance:

- Color:

- Thickness:

- Material:

- Maximum Operating Temperature:

- Minimum Operating Temperature:

- RoHS:

- Shelf Life:

- Tensile Strength:

- Ozone Resistance:

Z-Track (PFR)

SH1 (Foil Shielding)

Nylon White Thread

15 AWG Braided Ground Straps

Similar products

|

|

Liquid error (sections/main-product line 1090): invalid url input | |

| NAME | SHRINK-N-SHIELD® (2:1) EMI SHIELDED HEAT SHRINK TUBING | FLEX-SHIELD (HP) BRAIDED EMI SHIELDING SLEEVE | |

| DESCRIPTION | Shrink-N-Shield® (2:1) is a MIL-SPEC, heat-shrink tubing with a 2:1 shrink ratio that provides exceptional shielding from EMI, RFI and EMF. | A braided, expandable EMI, RFI and EMF shielding sleeve that is lightweight and flexible—an ideal solution for the aerospace industry. | |

| Closure | |||

| RoHS | RoHS-10 | RoHS-10 | |

| Abrasion Resistance | Best | ||

| Installation Type | Pull-Through | Pull-Through | |

| Purpose | EMI Shielding | Sleeve | |

| Min Temperature | Extreme | Moderate | |

| Minimum Operating Temperature | -40°F | -40°F | °F |

| Max Temperature | Moderate | Moderate | |

| Maximum Operating Temperature | 275°F | 302°F | °F |

| Flexibility | |||

| View | View | View |

Guides

Zip-Shield® (PFR) SH1 EMI Shielding w/Z-Track - CHILD

A protective jacket paired with an EMI shielding foil that features a pressure track closure, that is ideal for applications that will not experience flexing.

Drawing Number(s): ZT02-17-014

Selected Part Number: ZT02-17-014-0.375-B-B

Features

Benefits

Zip-Shield® (PFR) SH1 EMI Shielding w/Z-Track - CHILD

SHIELDING EFFECTIVENESS - SH1 (Foil Shielding)

Zip-Shield® (PFR) SH1 EMI Shielding w/Z-Track - CHILD

MATERIAL SPECIFICATIONS