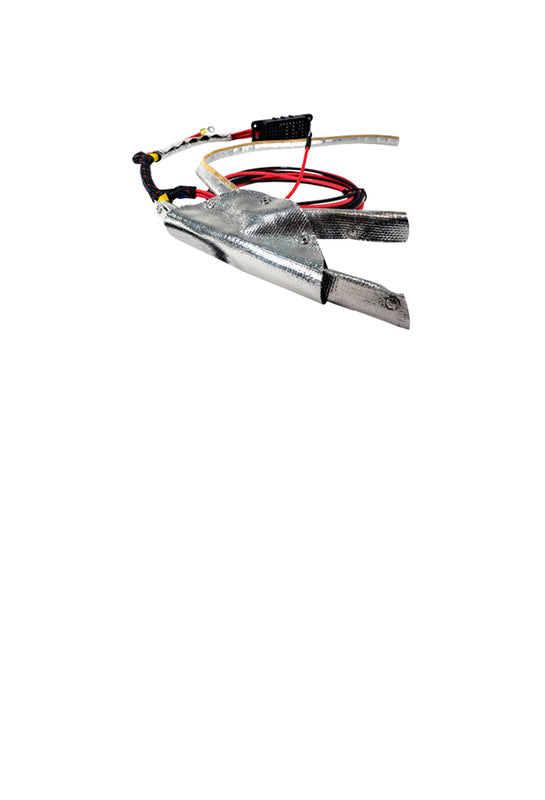

Extreme High Temperature Component Protection

PROBLEM: During an inspection, a power generating facility, determined they needed additional protection for certain critical infrastructure compon...

Read more about Extreme High Temperature Component Protection