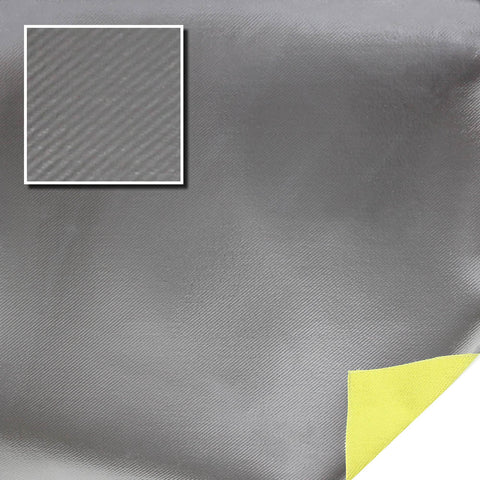

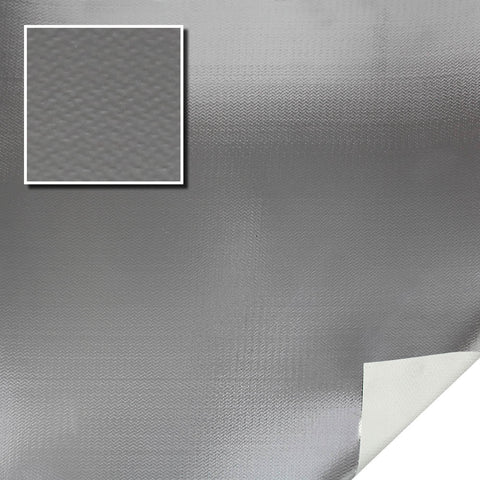

AFA-55 Aluminized Fiberglass with Adhesive

A Fully Customizable Aluminized Fiberglass Sheet Complete with a High-Temperature Acrylic Adhesive.

Overview

- We can cut to any shape or size

- Polycoated paper release liner for easy application

- Handles moderate temperatures of -40° to 356°F and flash exposures of 995°F

AFA-55 is an aluminized fiberglass sheet that contains a high-temperature acrylic adhesive covered on the backside and a removable paper backing. This material is the perfect customizable heat reflective solution for just about any shape or size you need. The AFA-55 material handles moderate temperatures of -40°F to 356°F (-40°C to 180°C) and flash exposures of 995°F (535°C).

Specifications

Similar Materials

|

|

|

|

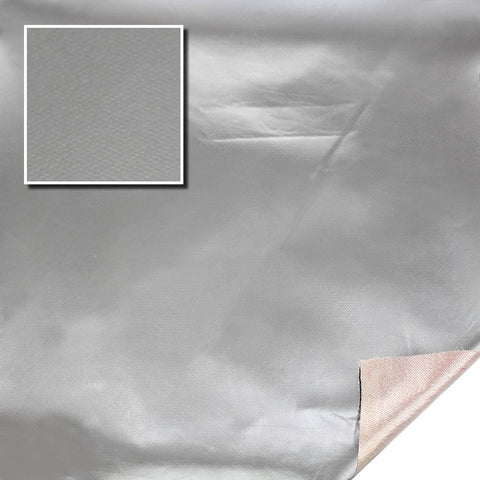

| NAME | ALK-19 HEAT REFLECTIVE WOVEN KEVLAR FABRIC | ALP-500 ALUMINIZED FIBERGLASS HEAT SHIELDING | ALS-5 FLEXIBLE ALUMINIZED FIBERGLASS HEAT SHIELDING |

| DESCRIPTION | High Strength Heat Reflective Woven Kevlar Fabric, Up to 177°C | Aluminized Fiberglass Heat Barrier, Up To 180°C | A thin, highly flexible aluminized fiberglass heat shielding material; shields up to 350°F (177°C). |

| RoHS | RoHS-11 | ||

| Abrasion Resistance | Good | Best | Good |

| Min Temperature | Extreme | Extreme | Extreme |

| Minimum Operating Temperature | -321°F | -58°F | -58°F |

| Max Temperature | Moderate | Moderate | Moderate |

| Maximum Operating Temperature | 350°F | 350°F | 350°F |

| Flexibility | Best | Better | Best |

| View | View | View |

AFA-55 Aluminized Fiberglass with Adhesive

A Fully Customizable Aluminized Fiberglass Sheet Complete with a High-Temperature Acrylic Adhesive.

Material Sprcification: 5016

- We can cut to any shape or size

- Polycoated paper release liner for easy application

- Handles moderate temperatures of -40° to 356°F and flash exposures of 995°F

SPECIFICATIONS

DESCRIPTION

AFA-55 is an aluminized fiberglass sheet that contains a high-temperature acrylic adhesive covered on the backside and a removable paper backing. This material is the perfect customizable heat reflective solution for just about any shape or size you need. The AFA-55 material handles moderate temperatures of -40°F to 356°F (-40°C to 180°C) and flash exposures of 995°F (535°C).