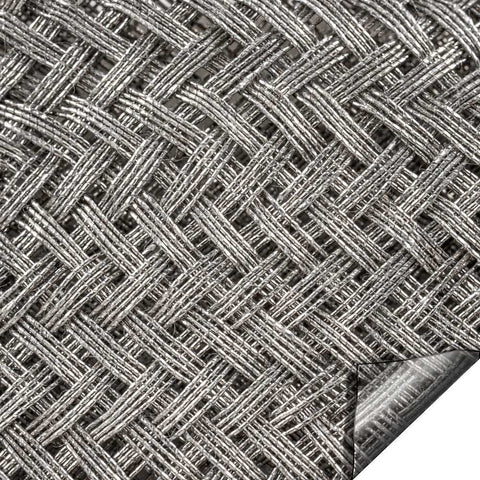

FSHP - Tin-Plated Copper with Nomex Core

A non-metallic material made of nomex threads and tin-plated copper foil strips to create a flexible, lightweight material.

Overview

- UL-rated meeting UL1441, VW-1

- Provides better EMI shielding

- Flexible, lightweight, and fluid resistant

The FSHP material is made of 2-ply twisted nomex threads that have tin-plated copper foil strips wound helically around each other. The flexible, lightweight EMI shielding material meets UL1441, VW-1 for flammability and has excellent fluid resistance. FSHP is the material used to construct our Flex-Shield™ (HP), which is an expandable EMI shielding sleeve. FSHP has an operational temperature range of -40°F to 302°F (-40°C to 150°C).

Specifications

Shielding Effectiveness

FSHP - Tin-Plated Copper with Nomex Core

A non-metallic material made of nomex threads and tin-plated copper foil strips to create a flexible, lightweight material.

Material Sprcification: 6106

- UL-rated meeting UL1441, VW-1

- Provides better EMI shielding

- Flexible, lightweight, and fluid resistant

SPECIFICATIONS

DESCRIPTION

The FSHP material is made of 2-ply twisted nomex threads that have tin-plated copper foil strips wound helically around each other. The flexible, lightweight EMI shielding material meets UL1441, VW-1 for flammability and has excellent fluid resistance. FSHP is the material used to construct our Flex-Shield™ (HP), which is an expandable EMI shielding sleeve. FSHP has an operational temperature range of -40°F to 302°F (-40°C to 150°C).

FSHP - Tin-Plated Copper with Nomex Core

SHIELDING EFFECTIVENESS