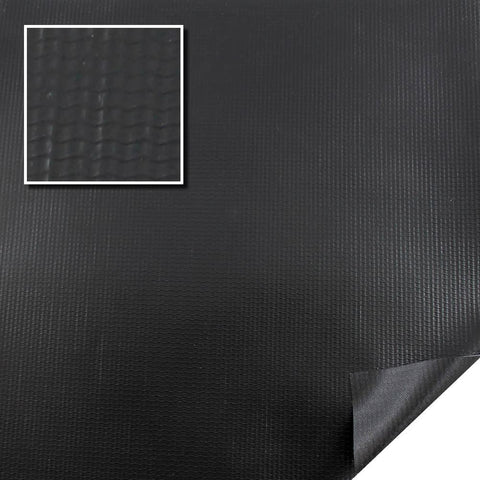

63-10 PVC Film - 10 mil

A flexible, lightweight PVC film that is 10-mil (0.010") thick.

Overview

- Meets MIL-I-631D, Type F, Form S, and MIL-I-631, Grade C, Class I, Category 1

- General purpose jacketing that is lightweight and flexible

- Best resistance to abrasion, good resistance to copper corrosion, fluid and fungus

The 63-10 jacketing is a 10-mil (0.010”) thick PVC film that is abrasion resistant, corrosion resistant, fluid resistant, UV stabilized, and contains anti-fungicide. The jacketing material meets specification MIL-I-631D, Type F, Form S, as well as MIL-I-631, Grade C, Class I, Category 1. The 63-10 jacketing has an operational temperature of -4°F to 221°F (-20°C to 105°C). The jacketing also has a dielectric rating of 600 volts/mil, handling up to 6,000 volts, a dielectric constant of 7.0 (1 kilocycle), and a dissipation factor of 0.14 min. (1 kilocycle). 63-10 can be configured for round, flat, or rectangular applications, can be heat sealed together with most closure systems, and can be equipped with an internal overlap flap to meet ground-based military application requirements.

Specifications

Similar Materials

|

|

|

|

| NAME | 63-20 PVC FILM - 20 MIL | PFR-18 POLYURETHANE FILM - 18 MIL | DVH-20 - PVC COATED POLYESTER - 20 MIL |

| DESCRIPTION | A flexible, medium-weight PVC film that is 20-mil (0.020") thick. | Extremely Flexible, Abrasion-Resistant, Polyurethane Film, 18 Mil | General Purpose PVC Coated Polyester Jacket, 20 Mil |

| RoHS | RoHS-10 | RoHS-10 | RoHS-10 |

| Abrasion Resistance | Best | Better | |

| Min Temperature | Low | Extreme | Moderate |

| Minimum Operating Temperature | -4°F | -67°F | -30°F |

| Max Temperature | Moderate | Moderate | Low |

| Maximum Operating Temperature | 221°F | 225°F | 185°F |

| Flexibility | Better | Good | |

| View | View | View |

63-10 PVC Film - 10 mil

A flexible, lightweight PVC film that is 10-mil (0.010") thick.

Material Sprcification: 1001-10

- Meets MIL-I-631D, Type F, Form S, and MIL-I-631, Grade C, Class I, Category 1

- General purpose jacketing that is lightweight and flexible

- Best resistance to abrasion, good resistance to copper corrosion, fluid and fungus

SPECIFICATIONS

DESCRIPTION

The 63-10 jacketing is a 10-mil (0.010”) thick PVC film that is abrasion resistant, corrosion resistant, fluid resistant, UV stabilized, and contains anti-fungicide. The jacketing material meets specification MIL-I-631D, Type F, Form S, as well as MIL-I-631, Grade C, Class I, Category 1. The 63-10 jacketing has an operational temperature of -4°F to 221°F (-20°C to 105°C). The jacketing also has a dielectric rating of 600 volts/mil, handling up to 6,000 volts, a dielectric constant of 7.0 (1 kilocycle), and a dissipation factor of 0.14 min. (1 kilocycle). 63-10 can be configured for round, flat, or rectangular applications, can be heat sealed together with most closure systems, and can be equipped with an internal overlap flap to meet ground-based military application requirements.